Press release

Preeflow volumetric adhesive dispensing from Intertronics helps ensure integrity of life-saving medical device

See accompanying video: http://youtu.be/_xkT2DNxCAoIntertronics’ customer BPR Medical, based in Mansfield, Nottingham, is a perfect example of a small British company which combines expertise, creativity and entrepreneurialism to design, develop and manufacture world-beating products for export worldwide and use in the United Kingdom, for which it was rewarded in 2012 with a Queen’s Award for Enterprise: Innovation. As with any manufacturing company, the success of its products depends to a considerable degree on assembly methods.

The company’s latest success story is the Bidirectional Firesafe™ Cannula Valve, used for in-home medical oxygen supplies to extinguish fires which can occur in the line between the concentrator and the user’s mask or nasal cannula. Such fires can occur if the line comes into contact with ambient flame – such as a candle – or more commonly if the patient is a smoker.

The UK’s Home Oxygen Service supports some 90,000 patients. In the US, accident & emergency units attend to in excess of 1,000 thermal burns a year caused by ignitions associated with home medical oxygen, of which smoking was by far the leading cause*.

*National Fire Protection Association estimate

Life and death integrity:

BPR’s unique inline Bidirectional Firesafe Cannula Valve extinguishes the fire by cutting off the oxygen supply. It is a development of an existing, unidirectional design and acts as a thermal fuse whereby the oxygen supply is cut off when a fusible component softens as a result of the heat from an approaching fire in the oxygen delivery tube. Integrity of operation is vital and could literally represent the difference between life and death.

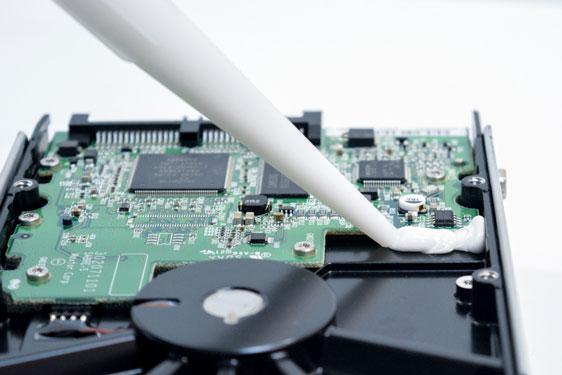

When BPR had chosen a two-part epoxy to bond both halves of the valve’s body, the next task was to find a dispensing solution that would assure deposition of a precise, repeatable volume of the adhesive, metered and mixed in the correct ratio, on to a cylindrical assembly. The resulting bond integrity would help ensure conformance for CE marking under European Medical Device Directive, as well as BPR’s unerring commitment to quality.

Technical Director Ben Johnson’s team evaluated a number of possibilities, including premixing and dispensing via a pinch tube valve. This yielded inconsistent results due to changes in viscosity which begin to occur naturally as soon as epoxy is mixed, exacerbated by temperature fluctuations. It also took an unacceptable amount of set-up and clean-up time.

The accuracy of volumetric dispensing:

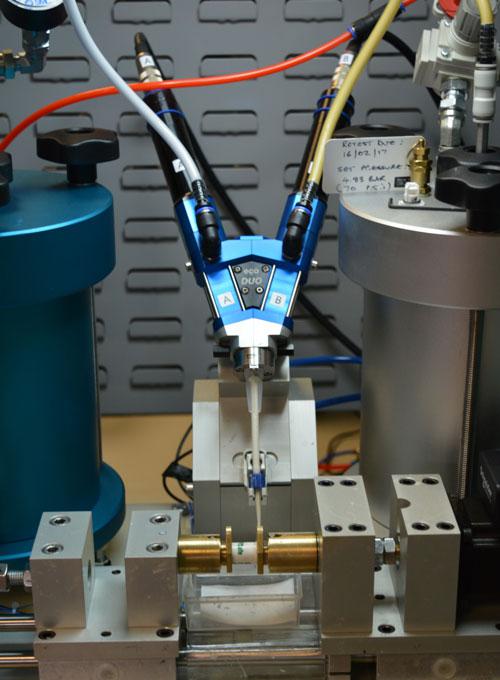

Having determined that volumetric technology would provide a better solution, BPR contacted Intertronics and two other vendors to arrange equipment demonstrations. Trials using the selected epoxy were conducted in a wide ambient temperature range, and rigorous pull, flexural and other testing of the assembled valve, revealed that the preeflow eco-DUO precision metering, mixing and dispensing system suggested by Intertronics was the correct solution. It offers ±1% dosing accuracy, >99% repeatability and can dispense volume flows of 0.2 to 32ml per minute, with a minimum volume of 0.01ml. The preeflow positive displacement technology means that the volume dispensed is not affected by viscosity changes in the material.

Key Customer Benefits were recognised as:

• Confidence of consistently high quality

• Increased productivity

• Decreased operating costs

• Time savings pre, during & post-operation

• Reduced material usage

• Reduced reject rates

• De-skilled assembly process

• Aesthetically superior products

The two alternative potential vendors and their systems were also evaluated, but Intertronics was selected – not only on the basis of the eco-DUO meeting BPR’s needs, but because of the lower total cost of ownership and promise of superior initial and ongoing support from Intertronics.

Ben Johnson and Product Development Programme Manager Mike Brudenell worked with Intertronics to configure the dispenser into its bespoke manufacturing jig, into which the two populated halves of the Firesafe valve body are manually loaded prior to being rotated whilst the epoxy is applied. Each of the 20,000 units per month produced at the time of writing is non-destructively tested, whilst regular samples are subject to a three-point flexural test.

The system operates an automatic purge at the end of the shift, eliminating the need for cleaning down. Control is via a preeflow plug ‘n’ mix interface and stored settings ensure consistency and repeatability, and eliminate daily set-up time. Thanks to preeflow’s accuracy, the volume of epoxy applied has been reduced to 0.05 g from the pinch tube valve’s 0.06 g.

Ben Johnson commented: “We had to go through a number of stringent processes to ensure the integrity of the bonding of the two body halves. An essential part of this was how the two-part epoxy adhesive was applied: to ensure a highly accurate, repeatable dose on a rotating jig, but also to maintain the correct dispense volume regardless of viscosity changes caused by temperature. After evaluating a number of options, we chose the eco-DUO from Intertronics as it provided the best results for both of these criteria.”

He continued: “Intertronics helped us choose a volumetric dispensing solution that was the best one for our needs. We’ve been very impressed with their expertise, they’re responsive and always on hand to support us with any queries or technical support we might need. The way they’ve helped us to integrate and set up the system means that we always achieve a consistently high level of process capability.”

Ben concluded: “Not only that, but we estimate our return on investment to be in the region of £2,000 a month.”

For further information please see application specific video at http://youtu.be/_xkT2DNxCAo or visit the Intertronics blog at www.adhere.uk.com.

"adhere” from Intertronics provides quality adhesive solutions to high technology, high performance assembly industries, incorporating outstanding levels of technical support and customer service.

The adhere concept covers their range of adhesives, encapsulants, coatings, sealants and tapes as well as the associated dispensing, curing and surface preparation equipment and materials used in the manufacturing and assembly processes. Also their Opti-tec brand of adhesives.

Intertronics have been certified to ISO 9001:2008 standard demonstrating their commitment to customer service and quality in delivery. Certification proves that the Intertronics quality management system ensures consistency and a continuous improvement ethic, leading to high levels of performance and customer satisfaction.

Sales partners include: Araldite, Thinky, Fisnar, DYMAX, Plato, Practical Components, Sipel, Techspray, 3DT Corona Treating Systems, SolderQuick, preeflow, Polytec PT, Opti-tec, Circuit Medic and ACC Silicones.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

blog: www.adhere.uk.com

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Preeflow volumetric adhesive dispensing from Intertronics helps ensure integrity of life-saving medical device here

News-ID: 370141 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for BPR

Compact Blender market: Lucrative Segments and their Underlying Factors | Planme …

"QY Research holds tons of experience in offering comprehensive and accurate analysis of global as well as regional markets. The report presented here is an industry-best compilation of detailed and quality research studies on the global Compact Blender market. It provides SWOT, PESTLE, and other important types of analysis to give a real and complete picture of the current and future scenarios of the global Compact Blender market. The analysts…

Global Pipe Bender Market Report, History and Forecast 2017-2028|AMOB Maquinas F …

Los Angeles, United States: The global Pipe Bender market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Pipe Bender market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and opportunities…

Dental Delivery System Market to Witness Massive Growth| Planmeca, VITALI, BPR S …

A latest survey on Dental Delivery System Market is conducted covering various organizations of the industry from different geographies to come up with 100+ page report. The study is a perfect mix of qualitative and quantitative information highlighting key market developments, challenges that industry and competition is facing along with gap analysis and new opportunity available and may trend in Dental Delivery System market. The report bridges the historical data…

Utility Task Vehicles Market 2017 Key Players – Polaris, John Deere, Kawasaki, …

The Global Utility Task Vehicles Market Research Report 2017 renders deep perception of the key regional market status of the Utility Task Vehicles Industry on a global level that primarily aims the core regions which comprises of continents like Europe, North America, and Asia and the key countries such as United States, Germany, China and Japan.

Request for sample of Utility Task Vehicles Market research report @ http://bit.ly/2tI7XwU

The report on…

Global Pipe Bender Sales Market - Baileigh Industrial, BPR CURVATRICI, Carell, C …

The Pipe Bender Sales Market Research Report 2017 is a professional and in-depth study on the current state of the Pipe Bender Sales industry.

Read Complete Report @ http://www.marketresearchstore.com/report/global-pipe-bender-sales-market-report-forecast-2017-132095

The key players are expected to tap onto these market opportunities to penetrate the market. Furthermore, the untapped opportunities in emerging economies will provide a considerable impetus to the small, medium, and large companies operating in the Global Pipe Bender Sales market. These…

Global Suction Pumps for Dental Offices and Laboratories Market 2017 : Gentilin, …

Global Suction Pumps for Dental Offices and Laboratories Market 2016 - 2017

A market study based on the " Suction Pumps for Dental Offices and Laboratories Market " across the globe, recently added to the repository of Market Research, is titled ‘Global Suction Pumps for Dental Offices and Laboratories Market 2017’. The research report analyses the historical as well as present performance of the worldwide Suction Pumps for Dental Offices and…