Press release

Why Semiconductor Devices Require an "Epitaxial Layer"

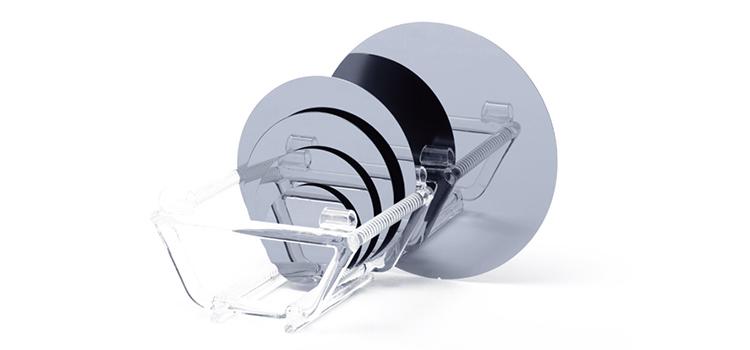

Origin of the Name "Epitaxial Wafer"Wafer preparation consists of two main steps: substrate preparation and epitaxial process. The substrate is made of semiconductor single crystal material and is typically processed to produce semiconductor devices. It can also undergo epitaxial processing to form an epitaxial wafer. Epitaxy refers to the process of growing a new single crystal layer on a carefully processed single crystal substrate. The new single crystal can be of the same material as the substrate (homogeneous epitaxy) or a different material (heterogeneous epitaxy). Since the new crystal layer grows in alignment with the substrate's crystal orientation, it is called an epitaxial layer. The wafer with the epitaxial layer is referred to as an epitaxial wafer (epitaxial wafer = epitaxial layer + substrate). Devices fabricated on the epitaxial layer are called "forward epitaxy," while devices fabricated on the substrate are referred to as "reverse epitaxy," where the epitaxial layer serves only as a support.

Homogeneous and Heterogeneous Epitaxy

Homogeneous Epitaxy: The epitaxial layer and substrate are made of the same material: e.g., Si/Si, GaAs/GaAs, GaP/GaP.

Heterogeneous Epitaxy: The epitaxial layer and substrate are made of different materials: e.g., Si/AlO, GaS/Si, GaAlAs/GaAs, GaN/SiC, etc.

Image: https://m191.goodao.net/uploads/Polished-Wafers.jpg

Polished Wafers

What Problems Does Epitaxy Solve?

Bulk single crystal materials alone are insufficient to meet the increasingly complex demands of semiconductor device fabrication. Therefore, in late 1959, the thin single crystal material growth technique known as epitaxy was developed. But how did epitaxial technology specifically help the advancement of materials? For silicon, the development of silicon epitaxy occurred at a critical time when the fabrication of high-frequency, high-power silicon transistors faced significant difficulties. From the perspective of transistor principles, achieving high frequency and power requires that the collector region's breakdown voltage be high, and the series resistance be low, meaning the saturation voltage should be small. The former requires high resistivity in the collector material, while the latter requires low resistivity, which creates a contradiction. Reducing the thickness of the collector region to reduce series resistance would make the silicon wafer too thin and fragile for processing, and lowering the resistivity would conflict with the first requirement. The development of epitaxial technology successfully resolved this issue. The solution was to grow a high resistivity epitaxial layer on a low-resistivity substrate. The device is fabricated on the epitaxial layer, ensuring the high breakdown voltage of the transistor, while the low-resistivity substrate reduces the base resistance and lowers the saturation voltage, solving the contradiction between the two requirements.

Image: https://m191.goodao.net/uploads/GaN-on-SiC.jpg

Additionally, epitaxial technologies for III-V and II-VI compound semiconductors such as GaAs, GaN, and others, including vapor phase and liquid phase epitaxy, have seen significant advancements. These technologies have become essential for the fabrication of many microwave, optoelectronic, and power devices. In particular, techniques like molecular beam epitaxy (MBE) and metal-organic chemical vapor deposition (MOCVD) have been successfully applied to thin layers, superlattices, quantum wells, strained superlattices, and atomic-scale thin epitaxial layers, laying a solid foundation for the development of new semiconductor fields such as "band engineering."

In practical applications, most wide-bandgap semiconductor devices are fabricated on epitaxial layers, with materials like silicon carbide (SiC) being used solely as substrates. Therefore, controlling the epitaxial layer is a critical factor in the wide-bandgap semiconductor industry.

Epitaxy Technology: Seven Key Features

1. Epitaxy can grow a high (or low) resistivity layer on a low (or high) resistivity substrate.

2. Epitaxy allows the growth of N (or P) type epitaxial layers on P (or N) type substrates, directly forming a PN junction without the compensation issues that arise when using diffusion to create a PN junction on a single crystal substrate.

3. When combined with mask technology, selective epitaxial growth can be performed in specific areas, enabling the fabrication of integrated circuits and devices with special structures.

4. Epitaxial growth allows for the control of doping types and concentrations, with the ability to achieve abrupt or gradual changes in concentration.

5. Epitaxy can grow heterogeneous, multi-layered, multi-component compounds with variable compositions, including ultra-thin layers.

6. Epitaxial growth can occur at temperatures below the melting point of the material, with a controllable growth rate, allowing for atomic-level precision in layer thickness.

7. Epitaxy enables the growth of single crystal layers of materials that cannot be pulled into crystals, such as GaN and ternary/quaternary compound semiconductors.

Various Epitaxial Layers and Epitaxial Processes

In summary, epitaxial layers offer a more easily controlled and perfect crystal structure than bulk substrates, which is beneficial for the development of advanced materials.

Media Contact

Company Name: Semicera

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=why-semiconductor-devices-require-an-epitaxial-layer]

Country: China

Website: https://www.semi-cera.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Why Semiconductor Devices Require an "Epitaxial Layer" here

News-ID: 3816560 • Views: …

More Releases from ABNewswire

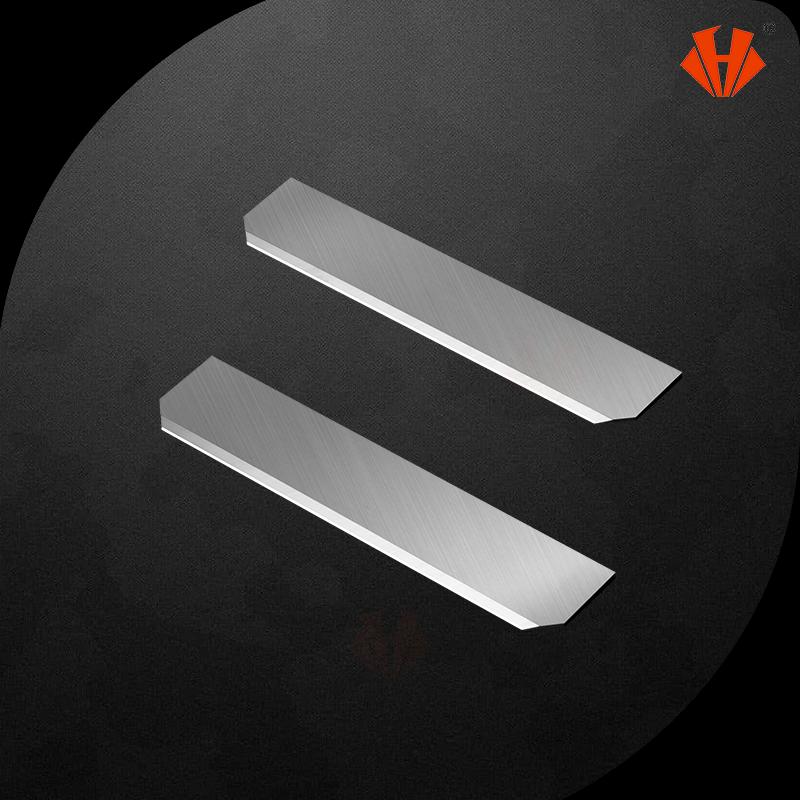

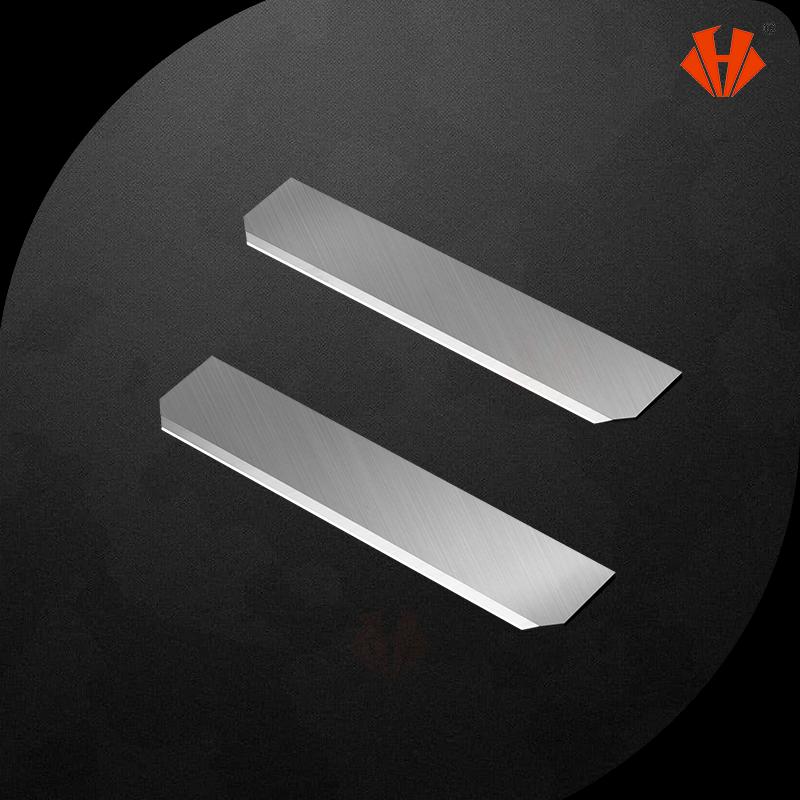

How to Check the "Cutting Edge" After a Tungsten Carbide Blades are Made

How to Check the "Cutting Edge" After a Tungsten Carbide blades are Made? We can think of it as :giving a final inspection to the armor and weapons of a general about to go into battle.

I. What Tools or equipment Are Used for Inspection?

1. "Extension of the Eyes" - Optical Magnifiers:

Tools: Bench magnifiers, illuminated magnifiers, stereomicroscopes.

What they're for: This is the most common, first-step inspection. Just like using a magnifying…

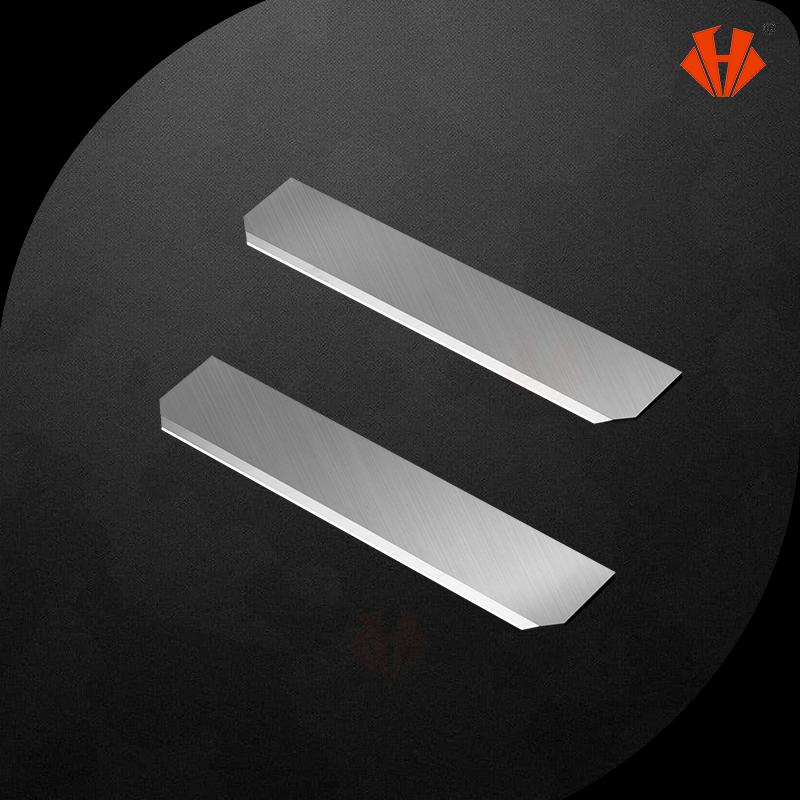

How to Check the "Cutting Edge" After a Tungsten Carbide Blades are Made

How to Check the "Cutting Edge" After a Tungsten Carbide blades are Made? We can think of it as :giving a final inspection to the armor and weapons of a general about to go into battle.

I. What Tools or equipment Are Used for Inspection?

1. "Extension of the Eyes" - Optical Magnifiers:

Tools: Bench magnifiers, illuminated magnifiers, stereomicroscopes.

What they're for: This is the most common, first-step inspection. Just like using a magnifying…

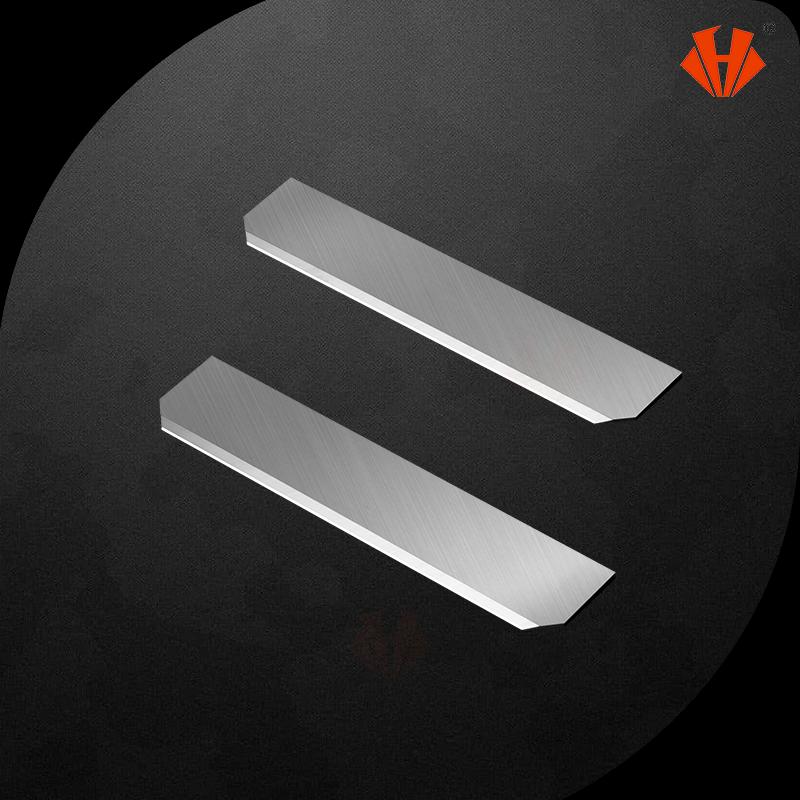

How to Check the "Cutting Edge" After a Tungsten Carbide Blades are Made

How to Check the "Cutting Edge" After a Tungsten Carbide blades are Made? We can think of it as :giving a final inspection to the armor and weapons of a general about to go into battle.

I. What Tools or equipment Are Used for Inspection?

1. "Extension of the Eyes" - Optical Magnifiers:

Tools: Bench magnifiers, illuminated magnifiers, stereomicroscopes.

What they're for: This is the most common, first-step inspection. Just like using a magnifying…

How to Check the "Cutting Edge" After a Tungsten Carbide Blades are Made

How to Check the "Cutting Edge" After a Tungsten Carbide blades are Made? We can think of it as :giving a final inspection to the armor and weapons of a general about to go into battle.

I. What Tools or equipment Are Used for Inspection?

1. "Extension of the Eyes" - Optical Magnifiers:

Tools: Bench magnifiers, illuminated magnifiers, stereomicroscopes.

What they're for: This is the most common, first-step inspection. Just like using a magnifying…

More Releases for Epitaxy

Semiconductor Epitaxy Foundry Market Size, Trends & Forecasts | Valuates Reports

Semiconductor Epitaxy Foundry Market Size

The global market for Semiconductor Epitaxy Foundry was valued at US$ 148130 million in the year 2024 and is projected to reach a revised size of US$ 240930 million by 2031, growing at a CAGR of 7.3% during the forecast period.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-17X14102/Global_Semiconductor_Epitaxy_Foundry_Market_Research_Report_2023?utm_source=openpr&utm_medium=referral

The production and manufacturing of compound semiconductors was originally based on the IDM business model, but in recent years, with the continuous maturity…

Semiconductor Epitaxy Wafer Market Size, Trends & Forecasts | Valuates Reports

Semiconductor Epitaxy Wafer Market Size

The global market for Semiconductor Epitaxy Wafer was valued at US$ 6160 million in the year 2024 and is projected to reach a revised size of US$ 9100 million by 2031, growing at a CAGR of 6.3% during the forecast period.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-37H19350/Global_Semiconductor_Epitaxy_Wafer_Market_Research_Report_2025?utm_source=openpr&utm_medium=referral&utm_campaign=semiconductor_epitaxy_wafer_2025

semiconductor wafer through processes like chemical vapor deposition (CVD) or molecular beam epitaxy (MBE). This layer enhances electrical properties, enabling precise control over…

Molecular Beam Epitaxy (MBE) Latest Market Analysis Report 2025

Global Info Research's report offers key insights into the recent developments in the global Molecular Beam Epitaxy (MBE) market that would help strategic decisions. It also provides a complete analysis of the market size, share, and potential growth prospects. Additionally, an overview of recent major trends, technological advancements, and innovations within the market are also included. Our report further provides readers with comprehensive insights and actionable analysis on the…

Global Molecular Beam Epitaxy (MBE) Market Outlook Report 2025

On Oct 14, Global Info Research released "Global Molecular Beam Epitaxy (MBE) Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report includes an overview of the development of the Molecular Beam Epitaxy (MBE) industry chain, the market status of Molecular Beam Epitaxy (MBE) Market, and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Molecular Beam…

Epitaxy Deposition Market to Witness Robust Expansion by 2031

The Epitaxy Deposition Market size is expected to grow at an annual average of CAGR 7% during the forecast period (2024-2031). Electronic devices, including integrated circuits (ICs), light-emitting diodes (LEDs), and solar cells, are commonly produced using a specific manufacturing process. Epitaxy deposition equipment is instrumental in the accurate control of thin film formation, enabling the construction of complex semiconductor devices with the necessary features. Typically, this equipment consists of…

Epitaxy Equipment Market Demand, Recent Trends and Developments Analysis 2027| I …

Los Angeles, United State: QY Research has evaluated the global Epitaxy Equipment market in its latest research report. The research study is a compilation of brilliant, thorough, and accurate analyses on different areas of the global Epitaxy Equipment market. The researchers have made it a point to explore hidden growth opportunities and pin-point key strategies of prominent players and the successes achieved with their implementation. The segmentation study provided in…