Press release

Detailed Financial Analysis of Dicyclopentadiene Production Cost Analysis (2025)

Introduction:Dicyclopentadiene (DCPD) is a chemical compound derived from the dimerization of cyclopentadiene, characterized by its strong odor and high reactivity. It is primarily used in the production of resins, particularly unsaturated polyester resins and epoxy resins, and finds applications in the manufacture of plastics, adhesives, paints, and flame retardants.

Setting up a Dicyclopentadiene manufacturing plant involves securing feedstock sources, investing in distillation and polymerization equipment, and adhering to strict environmental and safety regulations. Key considerations include plant location, availability of utilities, skilled workforce, and compliance with chemical industry standards and licensing requirements.

IMARC Group's report, titled "Dicyclopentadiene Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a dicyclopentadiene manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/dicyclopentadiene-manufacturing-plant-project-report/requestsample

Dicyclopentadiene Industry outlook 2025

The dicyclopentadiene (DCPD) industry is experiencing steady growth in 2025, driven by rising demand across automotive, construction, and electronics sectors. As industries prioritize high-performance, lightweight, and flame-resistant materials, DCPD-based products like unsaturated polyester resins and hydrocarbon resins have become increasingly vital. The global market, valued at approximately USD 856.6 million in 2024, is projected to grow significantly, with the Asia-Pacific region-particularly China and India-leading consumption due to rapid industrialization. Additionally, the industry is witnessing a shift toward sustainable and bio-based production methods, alongside innovations in process optimization using AI, positioning DCPD as a key chemical in the evolving materials landscape.

Key Cost Components of Setting Up a Dicyclopentadiene Plant

Detailed Process Flow

o Product Overview

o Unit Operations Involved

o Mass Balance and Raw Material Requirements

o Quality Assurance Criteria

o Technical Tests

Project Details, Requirements and Costs Involved:

o Land, Location and Site Development

o Plant Layout

o Machinery Requirements and Costs

o Raw Material Requirements and Costs

o Packaging Requirements and Costs

o Transportation Requirements and Costs

o Utility Requirements and Costs

o Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

o Capital Investments

o Operating Costs

o Expenditure Projections

o Revenue Projections

o Taxation and Depreciation

o Profit Projections

o Financial Analysis

Profitability Analysis:

o Total Income

o Total Expenditure

o Gross Profit

o Gross Margin

o Net Profit

o Net Margin

Key Cost Components of Setting Up a Dicyclopentadiene Plant

• Raw Material Procurement - Cost of cyclopentadiene and other feedstocks derived from petroleum.

• Land and Site Development - Expenses for land acquisition, site grading, infrastructure, and zoning compliance.

• Plant Machinery and Equipment - Investment in reactors, distillation columns, condensers, heat exchangers, and storage units.

• Utilities and Power Supply - Setup and ongoing costs for electricity, water, steam, and cooling systems.

• Construction and Civil Works - Costs associated with plant buildings, foundations, structural work, and safety infrastructure.

• Labor and Staffing - Hiring skilled workers, engineers, technicians, and administrative staff.

• Environmental and Safety Compliance - Expenses for pollution control systems, waste treatment, and regulatory certifications.

• Technology and Licensing Fees - Payments for patented manufacturing processes, licenses, or technical know-how.

• Transportation and Logistics - Infrastructure for transporting raw materials and finished products.

• Working Capital - Funds needed for day-to-day operations, including inventory, maintenance, and overhead costs.

Economic Trends Influencing Dicyclopentadiene Plant Setup Costs 2025

• Volatile Energy and Raw Material Prices: Rising global energy costs and fluctuating petroleum feedstock prices significantly impact sebacic acid plant capital and operating expenses.

• Regulatory Compliance and Infrastructure Costs: Stricter environmental laws and bureaucratic delays in regions like Gujarat increase infrastructure costs and complicate project implementation timelines.

• Capital Expenditure Overruns and Project Delays: Indian chemical projects often face cost overruns from planning inefficiencies, requiring disciplined execution and strategic capital management.

• Government Incentives and Supply Chain Shifts: India benefits from incentives and global supply chain diversification, encouraging investment through lower setup costs and domestic demand growth.

• Capital Access and Financing Costs: High industrial loan interest rates in India inflate financing costs, despite increased foreign direct investment in the chemical sector.

• Adoption of Automation, AI, and Green Tech: Modern plants using automation and green technologies reduce long-term costs but require higher initial capital investment and planning.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=18501&flag=C

Challenges and Considerations for Investors

• Raw Material Volatility: Prices of petroleum-based feedstocks like naphtha and cyclopentadiene are highly sensitive to global crude oil fluctuations.

• Regulatory Compliance: Stricter environmental norms require significant investment in pollution control, waste management, and safety systems.

• High Capital Expenditure: Establishing a DCPD plant involves substantial upfront costs for land, equipment, utilities, and technology.

• Financing Constraints: High industrial loan interest rates and limited access to low-cost capital may affect ROI.

• Project Execution Risks: Land acquisition delays, bureaucratic red tape, and potential cost overruns can hinder timely plant setup.

• Technology Choices: Deciding between conventional versus sustainable, AI-integrated, or energy-efficient technologies impacts long-term profitability.

• Market Competition: Global chemical players and substitute products may pressure prices and limit market share.

• Supply Chain Dependencies: Reliance on imported raw materials or machinery can pose logistical and cost-related challenges.

• Skilled Labor Availability: Recruiting and retaining trained personnel for high-tech operations may be difficult in certain regions.

• Policy Uncertainty: Shifts in trade policies, subsidies, or environmental regulations can affect long-term investment outlook.

Buy Now: https://www.imarcgroup.com/checkout?id=18501&method=1911

Conclusion

The dicyclopentadiene (DCPD) industry offers strong growth potential in 2025, supported by demand across key sectors and favorable government policies. However, setting up a plant involves navigating challenges such as high capital costs, raw material volatility, and regulatory compliance. Strategic planning, technology adoption, and efficient execution are essential for success, making DCPD a promising yet demanding investment opportunity for those prepared to manage its operational and market complexities.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Detailed Financial Analysis of Dicyclopentadiene Production Cost Analysis (2025) here

News-ID: 4085283 • Views: …

More Releases from IMARC Group

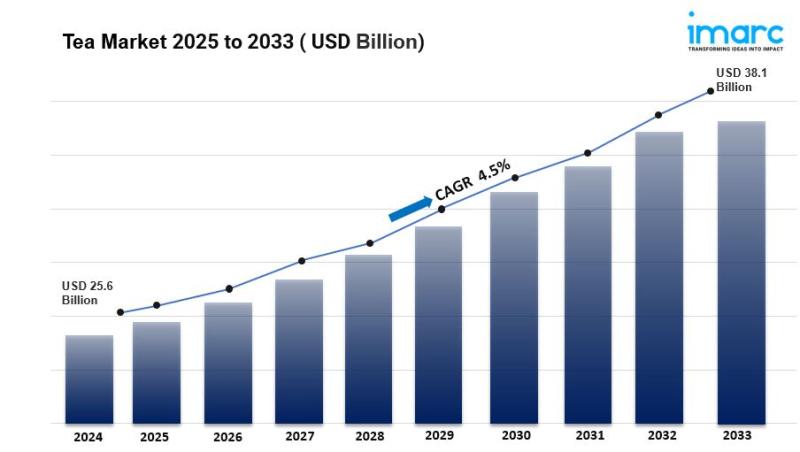

Tea Market is Projected to Grow USD 38.1 Billion by 2033 | At CAGR 4.5%

Tea Market Overview:

The global tea market was valued at USD 55.8 Billion in 2024 and is projected to reach USD 78.4 Billion by 2033, exhibiting a CAGR of 3.9% during the 2025-2033 forecast period. Growing consumer awareness about health benefits, rising demand for specialty and premium teas, and expanding café culture are driving this growth. The tea market size is expanding rapidly due to increasing consumer preference for natural and…

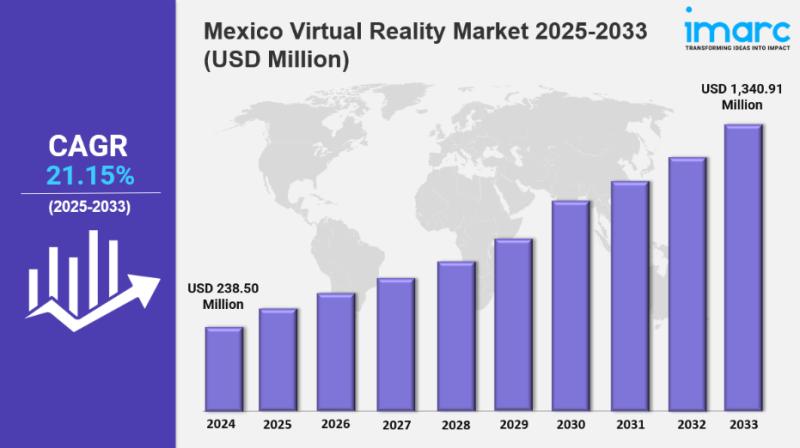

Mexico Virtual Reality Market 2025 : Industry Size to Reach USD 1,340.91 Million …

IMARC Group has recently released a new research study titled "Mexico Virtual Reality Market Size, Share, Trends and Forecast by Device Type, Technology, Component, Application, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico virtual reality market size reached USD 238.50 Million in 2024 and is projected to grow to USD…

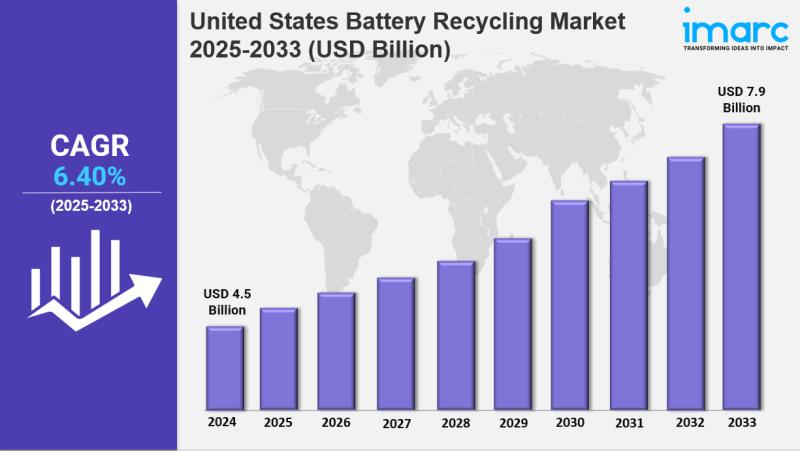

United States Battery Recycling Market Size to Hit USD 7.9 Billion by 2033: Tren …

IMARC Group has recently released a new research study titled "United States Battery Recycling Market Size, Share, Trends and Forecast by Type, Source, End Use, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The United States battery recycling market was valued at USD 4.5 Billion in 2024 and is projected to reach…

Magnesium Tungstate Production Plant Cost Report: Feasibility Study and Setup Re …

Introduction

Magnesium tungstate is an inorganic compound composed of magnesium, tungsten, and oxygen, typically represented by the chemical formula MgWO4. It is recognized for its robust crystalline structure and notable luminescent properties, making it valuable in various optical and electronic applications. The compound exhibits high density, chemical stability, and strong resistance to thermal stress, enabling effective performance under demanding environmental conditions. Magnesium tungstate is commonly used in scintillation detectors, phosphor materials,…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…