Press release

Methyl Acetate Production Cost Analysis and Setup Requirements in 2025

Introduction:Methyl Acetate (CH3COOCH3) is a clear, colorless liquid with a distinctive fruity aroma, widely used as an industrial solvent due to its low toxicity and effective dissolving power. It's found in diverse products like paints, glues, and nail polish removers. Beyond its solvent properties, it serves as a valuable chemical intermediate for synthesizing other compounds, showcasing its versatility across various industries.

Setting up a Methyl Acetate production plant typically involves the catalytic esterification of methanol and acetic acid. The process commonly utilizes reactive distillation to achieve high conversion and product purity, effectively handling azeotropes formed. Key considerations include securing consistent, high-quality raw material supply, investing in specialized distillation and reaction equipment, implementing robust safety measures for flammable liquids, and ensuring strict adherence to environmental regulations for waste management.

IMARC Group's report, titled "Methyl Acetate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a methyl acetate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/methyl-acetate-manufacturing-plant-project-report/requestsample

Methyl Acetate Industry outlook 2025

The Methyl Acetate (MA) industry anticipates robust growth in 2025, projected to reach around USD 7.25 billion with a CAGR of 3.5-8% through 2034. This is driven by its extensive use as a solvent in paints, coatings, and adhesives, fueled by construction and automotive sector growth. Demand for eco-friendly, low-VOC solvents also propels MA, given its lower toxicity. Its role as a chemical intermediate in pharmaceuticals and other specialized applications further supports market expansion.

Key Insights for Methyl Acetate Production Plant Setup

Detailed Process Flow

o Product Overview

o Unit Operations Involved

o Mass Balance and Raw Material Requirements

o Quality Assurance Criteria

o Technical Tests

Project Details, Requirements and Costs Involved:

o Land, Location and Site Development

o Plant Layout

o Machinery Requirements and Costs

o Raw Material Requirements and Costs

o Packaging Requirements and Costs

o Transportation Requirements and Costs

o Utility Requirements and Costs

o Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

o Capital Investments

o Operating Costs

o Expenditure Projections

o Revenue Projections

o Taxation and Depreciation

o Profit Projections

o Financial Analysis

Profitability Analysis:

o Total Income

o Total Expenditure

o Gross Profit

o Gross Margin

o Net Profit

o Net Margin

Key Cost Components of Setting Up a Methyl Acetate Plant

• Process Equipment: Reactors and specialized distillation columns are major investments.

• Land & Civil Works: Costs for industrial land, site preparation, and building construction.

• Utility Infrastructure: Systems for power, water, steam, and crucial effluent treatment plants (ETP) for compliance.

• Raw Material Inventory: Initial bulk purchase of methanol and acetic acid.

• Automation & Safety: Control systems, sensors, and essential safety/fire suppression equipment.

• Engineering & Labor: Design fees and wages for construction, installation, and commissioning.

• Regulatory Compliance: Significant costs for various environmental permits (e.g., from UPPCB) and adherence to Indian chemical safety rules.

• Contingency: A vital financial buffer for unforeseen expenses.

Economic Trends Influencing Methyl Acetate Plant Setup Costs 2025

• Construction Costs: Industrial construction costs in India are rising, affecting overall CAPEX for plant infrastructure.

• Raw Material Volatility: Prices of key feedstocks like methanol and acetic acid will fluctuate, impacting initial inventory and operational costs.

• Energy Prices: Volatile global energy markets and domestic tariffs will influence utility expenses.

• Government Policies: "Make in India" initiatives and focus on chemical sector growth may offer indirect benefits, but direct PLI schemes were not in Budget 2025.

• Labor Costs: Skilled labor costs are rising, affecting overall project expenses.

• Rupee Exchange Rate: A potentially weakening INR could increase import costs for specialized equipment.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=28467&flag=C

Challenges and Considerations for Investors

• High CAPEX: Substantial upfront investment is needed for specialized equipment and infrastructure.

• Raw Material Volatility: Fluctuating global prices of methanol and acetic acid directly impact profitability.

• Stringent Regulations: Navigating India's evolving environmental and safety rules (e.g., CMSR 2025 from central government, UPPCB guidelines) requires significant compliance investment.

• Market Competition: Competing with established players demands cost efficiency and differentiation.

• Skilled Workforce: Access to trained chemical engineers and operators in the region is crucial.

• Supply Chain Risks: Geopolitical factors can disrupt raw material sourcing and product distribution.

Buy Now: https://www.imarcgroup.com/checkout?id=28467&method=1911

Conclusion

The Methyl Acetate industry anticipates robust growth in 2025, driven by its versatility as a solvent in paints and coatings, and as a chemical intermediate. Establishing a plant in Noida, Uttar Pradesh, involves substantial capital for specialized equipment and infrastructure. Investors must navigate economic trends like rising construction and raw material costs, while also adhering to India's stringent environmental and safety regulations. Overcoming market competition, ensuring a skilled workforce, and building resilient supply chains are crucial for a successful and sustainable venture.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Methyl Acetate Production Cost Analysis and Setup Requirements in 2025 here

News-ID: 4089452 • Views: …

More Releases from IMARC Group

E-Waste Recycling Plant Report 2025: Market Trends, Project Cost & Industry Outl …

E-waste, also known as electronic waste or waste electrical and electronic equipment (WEEE), is discarded electronic devices and components renowned for their valuable recoverable materials, environmental significance, and resource recovery potential. Known for its high content of precious metals, rare earth elements, and recyclable plastics, e-waste outperforms many conventional waste streams in applications like metal recovery, material reclamation, circular economy initiatives, and sustainable resource management. Its ability to yield multiple…

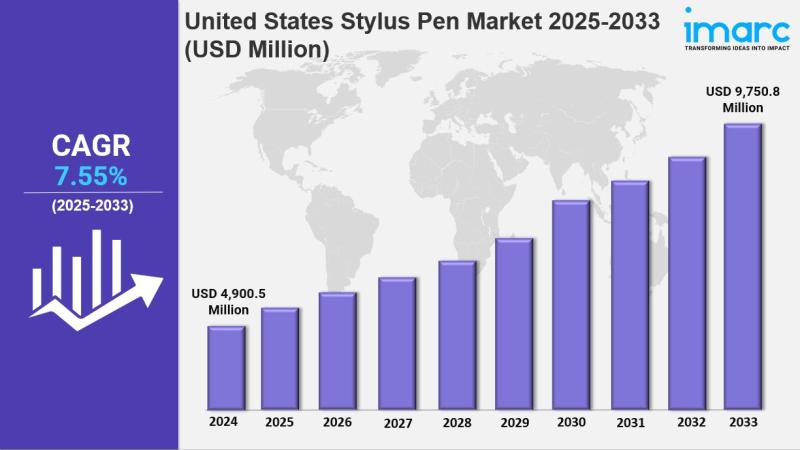

United States Stylus Pen Market Size, Trends, Growth and Forecast 2025-2033

IMARC Group has recently released a new research study titled "United States Stylus Pen Market Report by Product Type (Resistive Stylus, Capacitive Stylus, Active Stylus), Distribution Channel (Online, Offline), Application (Smart Phones, Tablets, Interactive Whiteboards), End User (OEM, Retail), and Region 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

United States Stylus Pen Market…

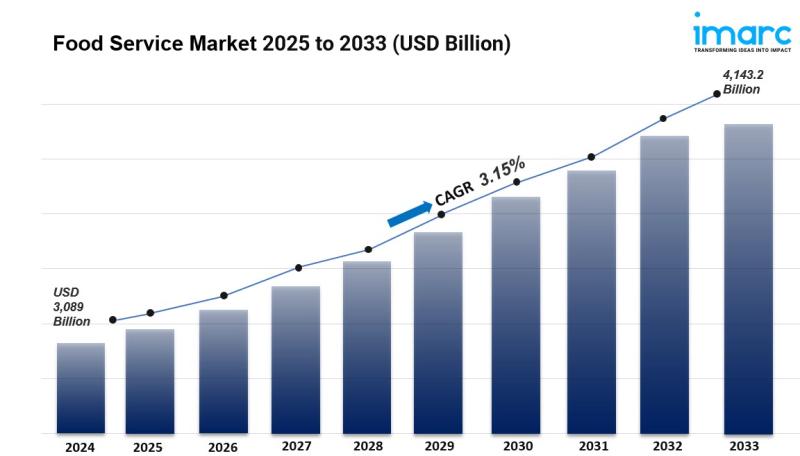

Food Service Market Size, Share, Growth And Trends Report 2025-2033

Food Service Market Size and Outlook 2025 to 2033

The global food service market size reached USD 3,089 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 4,143.2 Billion by 2033, exhibiting a CAGR of 3.15% during 2025-2033. Asia Pacific currently dominates the market, holding a significant market share in 2024. The market is experiencing stable growth driven by growing health-consciousness among individuals, rising number of online…

Coconut Processing Plant Cost Report 2025: Raw Materials, Process Flow & Profita …

Coconut, also known as the "tree of life," is a versatile tropical fruit renowned for its exceptional nutritional value, diverse applications, and natural characteristics. Known for its high nutritious content, natural oils, and versatility, coconut outperforms many conventional agricultural products in applications like food and beverage products, personal care items, industrial materials, and nutritional supplements. Its ability to provide multiple value-added products from a single source and excellent shelf stability…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…