Press release

Lithium Hexafluorophosphate Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview

Introduction:Lithium hexafluorophosphate (LiPF6) is a critical lithium salt primarily used as the electrolyte component in commercial lithium-ion batteries (LIBs), powering everything from electric vehicles to smartphones. Dissolved in organic solvents, it facilitates the movement of lithium ions between the anode and cathode during charging and discharging. Its success stems from a balanced set of properties, including high ionic conductivity, electrochemical stability, and the ability to form a protective layer on battery electrodes, crucial for battery performance and lifespan.

Setting up a Lithium Hexafluorophosphate production plant is a complex process, typically involving the reaction of lithium fluoride (LiF) with phosphorus pentafluoride (PF5), often in anhydrous hydrofluoric acid (HF) as a solvent. The process demands stringent control over moisture and impurities to achieve battery-grade purity. Key considerations for a plant in Noida include substantial investment in specialized, corrosion-resistant reactors and purification equipment, advanced safety protocols for handling hazardous chemicals like HF and PF5, and strict adherence to environmental regulations for waste management.

IMARC Group's report, titled "Lithium Hexafluorophosphate Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a lithium hexafluorophosphate manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/lithium-hexafluorophosphate-manufacturing-plant-project-report/requestsample

Lithium Hexafluorophosphate Industry outlook 2025

The Lithium Hexafluorophosphate (LiPF6) industry is set for robust growth in 2025, driven primarily by the surging global demand for lithium-ion batteries in electric vehicles (EVs) and energy storage systems (ESS). Projected to reach approximately USD 3.5 billion with a CAGR of around 12.9% from 2025-2033, the market benefits from increasing EV adoption and clean energy policies. Asia-Pacific, particularly China, is expected to dominate. Challenges include raw material price volatility and high production costs, though ongoing innovation focuses on purity and sustainable methods.

Key Insights for Lithium Hexafluorophosphate Manufacturing Plant Setup

Detailed Process Flow

o Product Overview

o Unit Operations Involved

o Mass Balance and Raw Material Requirements

o Quality Assurance Criteria

o Technical Tests

Project Details, Requirements and Costs Involved:

o Land, Location and Site Development

o Plant Layout

o Machinery Requirements and Costs

o Raw Material Requirements and Costs

o Packaging Requirements and Costs

o Transportation Requirements and Costs

o Utility Requirements and Costs

o Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

o Capital Investments

o Operating Costs

o Expenditure Projections

o Revenue Projections

o Taxation and Depreciation

o Profit Projections

o Financial Analysis

Profitability Analysis:

o Total Income

o Total Expenditure

o Gross Profit

o Gross Margin

o Net Profit

o Net Margin

Key Cost Components of Setting Up a Lithium Hexafluorophosphate Plant

• Specialized Equipment: High-purity, corrosion-resistant reactors, purification units, and drying systems are major investments.

• Raw Material Costs: Lithium fluoride (LiF) and phosphorus pentafluoride (PF5) are expensive and demand careful sourcing.

• Safety Infrastructure: Extensive safety systems for handling highly corrosive and hazardous chemicals (like anhydrous HF) are crucial and costly.

• Environmental Compliance: Strict regulations in India necessitate significant investment in advanced effluent treatment and emissions control.

• R&D & Quality Control: Continuous investment in testing and quality assurance is paramount for battery-grade LiPF6.

• Land & Utilities: Acquiring suitable industrial land in Noida and establishing robust utility connections (power, water) contributes significantly to CAPEX.

• Skilled Labor: Hiring and training specialized personnel for chemical synthesis and safety operations adds to costs.

• Contingency: A substantial buffer is essential for unforeseen technical or regulatory challenges.

Economic Trends Influencing Lithium Hexafluorophosphate Plant Setup Costs 2025

• Raw Material Price Volatility: High fluctuations in lithium fluoride (LiF) and phosphorus pentafluoride (PF5) prices, driven by EV battery demand, will impact costs. Anhydrous HF prices are also on an upward trend.

• Construction Cost Inflation: Industrial construction costs in India are rising, affecting overall CAPEX for specialized facilities.

• Energy Costs: Being energy-intensive, fluctuating electricity tariffs in Uttar Pradesh will impact operational expenses.

• Government Policies: India's PLI schemes for batteries/EVs could offer indirect support, but regulatory compliance costs remain significant.

• Rupee Exchange Rate: A potentially weakening INR (towards ₹87.5/USD by end-2025) will increase costs for imported specialized equipment.

• Interest Rates: RBI's monetary policy may offer favorable borrowing conditions for large projects.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=9255&flag=C

Challenges and Considerations for Investors

• Raw Material Scarcity - Limited high-purity lithium and fluorine sources

• High Production Costs - Complex synthesis and purification of lithium hexafluorophosphate

• Safety Risks - Handling corrosive, toxic chemicals used in lithium hexafluorophosphate manufacturing

• Regulatory Compliance - Strict environmental and hazardous material regulations

• Market Demand Volatility - Lithium hexafluorophosphate demand tied to battery and EV industries

• Technological Expertise Required - Advanced processes and skilled workforce needed

• Supply Chain Risks - Dependence on geopolitically sensitive raw material suppliers

• Quality Assurance Challenges - Maintaining consistent battery-grade lithium hexafluorophosphate purity

Buy Now: https://www.imarcgroup.com/checkout?id=9255&method=1911

Conclusion

The Lithium Hexafluorophosphate (LiPF6) industry is a high-growth sector, projected to reach approximately USD 3.5 billion in 2025 with a CAGR of around 12.9% through 2033. This robust growth is primarily driven by the escalating global demand for lithium-ion batteries in electric vehicles (EVs) and energy storage systems (ESS). As the critical electrolyte component, LiPF6 benefits from increasing EV adoption rates and worldwide clean energy initiatives. While raw material price volatility and high production costs pose challenges, continuous innovation in purity and sustainable manufacturing methods are key trends shaping its promising future.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lithium Hexafluorophosphate Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4089636 • Views: …

More Releases from IMARC Group

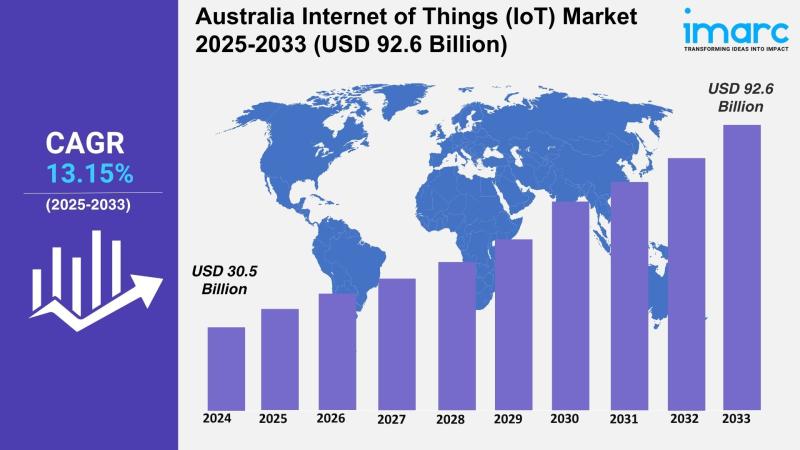

Australia Internet of Things Market Projected to Reach USD 92.6 Billion by 2033

The latest report by IMARC Group, titled "Australia Internet of Things Market Size & Forecast 2033," offers a comprehensive analysis of the Australia Internet of Things market growth. The report includes competitor and regional analysis, along with a detailed breakdown of the market segmentation. The Australia Internet of Things market size reached USD 30.5 billion in 2024. Looking forward, IMARC Group expects the market to reach USD 92.6 billion by…

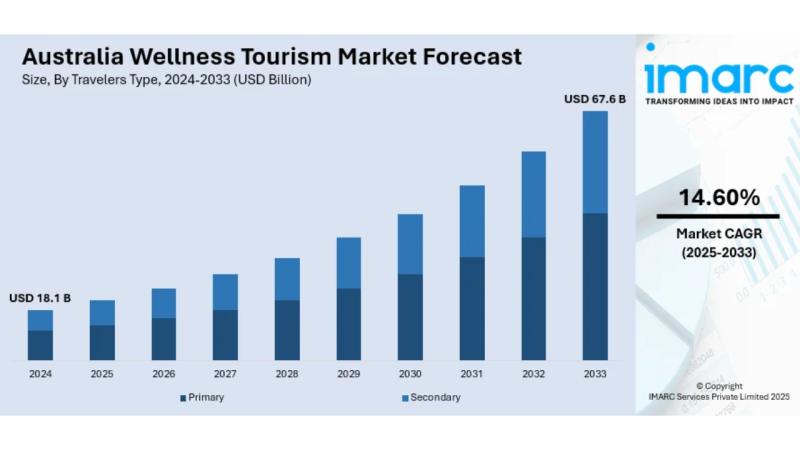

Australia Wellness Tourism Market to Reach USD 67.6 Billion by 2033

The latest report by IMARC Group, titled "Australia Wellness Tourism Market Size, Share, Trends 2033," offers a comprehensive analysis of the Australia wellness tourism market growth. The report includes competitor and regional analysis, along with a detailed breakdown of the market segmentation. The Australia wellness tourism market size reached USD 18.1 billion in 2024. Looking forward, IMARC Group expects the market to reach USD 67.6 billion by 2033, exhibiting a…

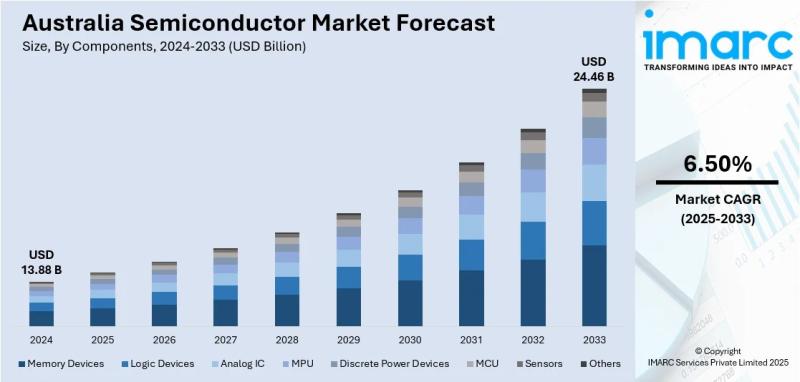

Australia Semiconductor Market Projected to Reach USD 24.46 Billion by 2033

The latest report by IMARC Group, titled "Australia Semiconductor Market Size and Forecast 2033," offers a comprehensive analysis of the Australia semiconductor market growth. The report includes competitor and regional analysis, along with a detailed breakdown of the market segmentation. The Australia semiconductor market size reached USD 13.88 billion in 2024. Looking forward, IMARC Group expects the market to reach USD 24.46 billion by 2033, exhibiting a CAGR of 6.50%…

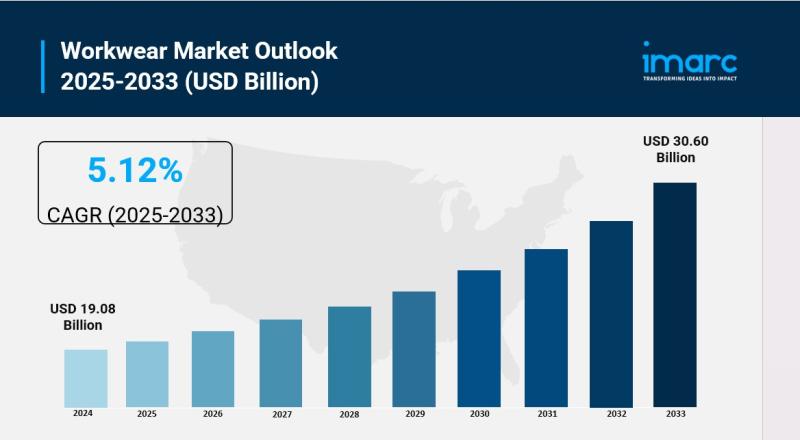

Workwear Market is Expected to Reach USD 30.60 Billion by 2033 | At CAGR 5.12%

Overview - Workwear Market

The global workwear market is experiencing steady growth, driven by the rising emphasis on workplace safety, functionality, and comfort. Workwear includes uniforms and protective clothing designed for industries such as construction, healthcare, oil & gas, mining, manufacturing, and corporate offices. The market is expanding due to stringent safety regulations, increasing industrial activities, and a growing focus on professional appearance across sectors. Additionally, the rising demand for specialized…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…