Press release

Diethylene Glycol Monobutyl Ether Production Cost Analysis 2025

Introduction:Diethylene Glycol Monobutyl Ether (DEGBE) is a colorless, odorless liquid that belongs to the glycol ether family. It is commonly used as a solvent in various applications, including paints, coatings, cleaning products, and inks, due to its excellent solvency properties and low volatility. DEGBE is favored for its ability to dissolve a wide range of substances, making it an effective medium for formulations requiring high-performance solvents. Additionally, it has a relatively low toxicity profile compared to other solvents, which enhances its appeal in industrial and consumer products.

Setting up a diethylene glycol monobutyl ether production plant requires careful planning, including site selection, equipment procurement, and compliance with safety regulations. Key equipment includes reactors, distillation columns, and storage tanks for raw materials and finished products. Securing a reliable supply chain for feedstocks, such as diethylene glycol and butanol, is essential. Additionally, adherence to environmental regulations and implementation of safety protocols are critical to ensure efficient and safe operations throughout the production process. Proper workforce training and quality control measures will also contribute to the plant's success.

Request for a Sample Report: https://www.imarcgroup.com/diethylene-glycol-monobutyl-ether-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Diethylene Glycol Monobutyl Ether Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a diethylene glycol monobutyl ether production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Diethylene Glycol Monobutyl Ether Industry Outlook 2025

The Diethylene Glycol Monobutyl Ether (DEGBE) industry is poised for growth by 2025, driven by increasing demand in sectors such as paints, coatings, and cleaning products. Its effective solvency properties and low toxicity make it a preferred choice for manufacturers seeking safer alternatives to traditional solvents. Additionally, the rising focus on environmentally friendly formulations is boosting DEGBE's appeal. As industries prioritize sustainability and performance, the DEGBE market is expected to expand, supported by innovations in production processes and a growing emphasis on regulatory compliance.

Key Insights for Diethylene Glycol Monobutyl Ether Production Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=10716&flag=C

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now: https://www.imarcgroup.com/checkout?id=10716&method=1911

Key Cost Components of Setting Up a Diethylene Glycol Monobutyl Ether Plant

• Capital Investment: This includes expenses for land, civil works, machinery, and production technology (reactors, distillation columns, etc.).

• Utilities and Labor: Ongoing operational expenses for energy, water, and skilled labor are significant cost components.

• Regulatory Compliance: Costs associated with permits, environmental and safety compliance, and waste treatment are mandatory.

• Logistics: Transportation and packaging expenses for both raw materials and the final product are crucial for overall cost.

Economic Trends Influencing Diethylene Glycol Monobutyl Ether Setup Costs 2025

• Environmental Regulations: Stricter VOC and carbon emissions regulations increase capital expenditure for compliance, including investment in emissions control systems.

• Global Supply Chain Disruptions: Geopolitical issues and logistical challenges lead to increased freight costs and delays for machinery and raw materials.

• Rising Energy Costs: Inflation in electricity and fuel prices raises the operational costs of manufacturing and utilities.

• Interest Rates and Financing: High borrowing costs impact project financing, increasing the overall cost of capital for a new setup.

Challenges and Considerations for Investors

• Raw Material Price Volatility: DGBE is produced from ethylene oxide and n-butanol. Fluctuations in the price of these feedstocks, particularly those linked to crude oil, can affect production costs and profit margins.

• Competition from Substitutes: The market faces competition from alternative solvents. Innovation in bio-based and other eco-friendly alternatives presents a risk to DGBE's market position.

• Safety and Handling: While considered to have low acute toxicity, DGBE is a combustible liquid and can cause eye and skin irritation. Proper handling and storage are crucial, and any related incidents could lead to negative publicity or regulatory action.

• Supply Chain Disruptions: Geopolitical events and natural disasters can disrupt global supply chains, impacting the availability and price of DGBE.

Conclusion

This report aims to serve as a practical guide for entrepreneurs, investors, and industrial planners exploring opportunities in diethylene glycol monobutyl ether production. By understanding the cost structure, market dynamics, and operational challenges, stakeholders can make informed decisions and devise sustainable strategies for entry and expansion in the sector.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Diethylene Glycol Monobutyl Ether Production Cost Analysis 2025 here

News-ID: 4140215 • Views: …

More Releases from IMARC Services Private Limited

Brazil EdTech Market Size, Share, Growth, and Forecast 2025-2033

Brazil EdTech Market Overview

Market Size in 2024: USD 5.41 Billion

Market Forecast in 2033: USD 14.64 Billion

Market Growth Rate: 11.7% (2025-2033)

According to the latest report by IMARC Group, the Brazil edtech market size was valued at USD 5.41 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 14.64 Billion by 2033, exhibiting a CAGR of 11.7% from 2025-2033.

Brazil EdTech Industry Trends and Drivers:

Expanding Digital Access and…

Brazil 3PL Market Analysis: Key Trends, Drivers & Forecast 2025-2033

Brazil 3pl Market Overview

Market Size in 2024: USD 29.3 Billion

Market Forecast in 2033: USD 56.0 Billion

Market Growth Rate: 7.49% (2025-2033)

According to the latest report by IMARC Group, the Brazil 3pl market size was valued at USD 29.3 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 56.0 Billion by 2033, exhibiting a CAGR of 7.49% from 2025-2033.

Brazil 3pl Industry Trends and Drivers:

Brazil 3PL logistics market for…

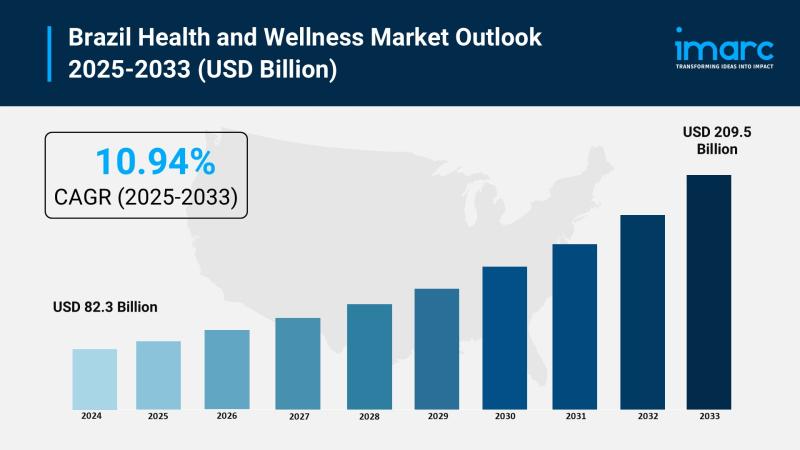

Brazil Health and Wellness Market: Future Outlook 2025-2033

Brazil Health and Wellness Market: Future Outlook 2025-2033

Brazil Health And Wellness Market Overview

Market Size in 2024: USD 82.3 Billion

Market Forecast in 2033: USD 209.5 Billion

Market Growth Rate: 10.94% (2025-2033)

According to the latest report by IMARC Group, the Brazil health and wellness market size was valued at USD 82.3 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 209.5 Billion by 2033, exhibiting a CAGR of 10.94%…

Brazil Carbon Credits Market Size, Share, Growth, Trends, Report 2025-2033

Brazil Carbon Credits Market Overview

Market Size in 2024: USD 2.11 Billion

Market Forecast in 2033: USD 24.84 Billion

Market Growth Rate: 28.4% (2025-2033)

According to the latest report by IMARC Group, the Brazil carbon credits market size was valued at USD 2.11 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 24.84 Billion by 2033, exhibiting a CAGR of 28.4% from 2025-2033.

Brazil Carbon Credits Industry Trends and Drivers:

Increasing…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…