Press release

Generic Injectables Manufacturing Cost Report 2025: Plant Setup Economics and Financial Outlook

Generic injectables are pharmaceutical formulations administered directly into the body through injections, offering the same therapeutic benefits as branded versions once patent protection expires. These products play a vital role in healthcare by providing cost-effective, safe, and accessible treatment options for a wide range of conditions, including chronic and acute diseases.Setting up a generic injectables manufacturing plant requires adherence to stringent regulatory standards, advanced sterile production facilities, and high-quality control systems. Investment in cleanroom infrastructure, automated filling lines, and compliance with Good Manufacturing Practices (GMP) is essential to ensure safety, efficacy, and scalability in production.

IMARC Group's report, titled "Generic Injectables Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a generic injectables manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/generic-injectables-manufacturing-plant-project-report/requestsample

Generic injectables Industry outlook 2025:

The generic injectables industry outlook for 2025 remains highly promising, driven by patent expirations of blockbuster biologics, rising demand for cost-effective treatments, and increasing prevalence of chronic diseases. Expanding healthcare access in emerging markets and growing preference for injectable drug delivery are expected to accelerate market growth. Strategic collaborations, investments in advanced manufacturing technologies, and regulatory support for biosimilars are further fueling competition and innovation. However, challenges such as stringent quality requirements, supply chain constraints, and high production costs may impact profitability. Overall, the industry is projected to witness strong growth, with significant opportunities across global markets.

Key Insights for Generic Injectables Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Generic Injectables Plant:

• Infrastructure Development: Land acquisition, facility construction, and cleanroom setup.

• Equipment & Machinery: Sterile filling lines, lyophilizers, autoclaves, and quality testing instruments.

• Regulatory Compliance: Costs for Good Manufacturing Practices (GMP) certification, FDA/EMA approvals, and documentation.

• Raw Materials & Packaging: Active pharmaceutical ingredients (APIs), excipients, vials, ampoules, and labeling.

• Utilities & Maintenance: Water purification systems, HVAC, power supply, and facility upkeep.

• Workforce & Training: Hiring skilled professionals and ongoing staff training programs.

• Quality Control & Assurance: Analytical labs, sterility testing, and validation procedures.

• Operational Expenses: Supply chain logistics, licensing, insurance, and overheads.

Economic Trends Influencing Generic Injectables Plant Setup Costs 2025:

• Material Price Volatility: Fluctuations in the cost of active pharmaceutical ingredients (APIs) and packaging materials impact overall capital requirements.

• Global Inflation Pressures: Rising construction, labor, and utility costs increase plant establishment expenses.

• Supply Chain Disruptions: Geopolitical tensions and shipping delays drive up logistics and procurement costs.

• Regulatory Stringency: Stricter compliance standards demand higher investments in quality control and validation systems.

• Technological Advancements: Automation and digital solutions raise initial setup costs but reduce long-term operational expenses.

• Market Competition: Expanding generic pipelines intensify pricing pressures, influencing return on investment forecasts.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7630&flag=C

Challenges and Considerations for Investors in Generic Injectables Plant Projects:

• High Capital Requirements: Significant upfront investment needed for sterile infrastructure, equipment, and regulatory approvals.

• Regulatory Compliance Risks: Stringent global standards demand continuous audits, certifications, and adherence to GMP.

• Complex Manufacturing Processes: Sterile injectable production requires advanced technology and skilled workforce.

• Supply Chain Vulnerabilities: Dependence on APIs and specialized packaging materials can cause delays and cost overruns.

• Competitive Market Dynamics: Price erosion due to intense competition from established players and biosimilars.

• Long Approval Timelines: Lengthy regulatory review processes may delay market entry and impact ROI.

• Operational Sustainability: Ensuring consistent quality, scalability, and cost efficiency over time.

Conclusion:

The establishment of a generic injectables manufacturing plant presents significant opportunities in a rapidly expanding pharmaceutical market, fueled by rising demand for cost-effective treatments and patent expirations of key drugs. However, the sector requires substantial investment, strict compliance with global regulatory standards, and advanced technological capabilities to ensure product quality and safety. Investors must carefully assess capital requirements, operational challenges, and market competition before committing to such projects. With strategic planning, strong supply chain management, and a focus on innovation, generic injectables plants can deliver long-term growth potential and contribute to improved global healthcare accessibility.

Buy Now: https://www.imarcgroup.com/checkout?id=7630&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Generic Injectables Manufacturing Cost Report 2025: Plant Setup Economics and Financial Outlook here

News-ID: 4153108 • Views: …

More Releases from IMARC Group

How Is the Frozen Food Market Growing with Expanding Retail and E-Commerce Chann …

MARKET OVERVIEW

The global frozen food market size reached USD 261.9 Billion in 2024 and is projected to reach USD 360 Billion by 2033, growing at a CAGR of 3.59% during the forecast period of 2025-2033. Factors such as rising consumer focus on health and wellness, expanding e-commerce, advancements in logistics and preservation technologies, and growing demand for convenience are driving the market.

STUDY ASSUMPTION YEARS

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period:…

Setting up a Magnet Manufacturing Plant Cost Report 2025: Business Plan, Infrast …

Introduction

A magnet is a material or object that produces a magnetic field, enabling it to attract ferromagnetic materials such as iron, nickel, and cobalt. Magnets are broadly classified into permanent magnets, which retain their magnetic properties without external power, and electromagnets, which generate magnetism through electric current. The strength and durability of magnets depend on their material composition, commonly including neodymium, samarium-cobalt, alnico, and ferrite. These materials are engineered to…

India Vegan Food Market Size, Share & Growth Forecast by 2033

MARKET OVERVIEW

The India vegan food market size was USD 1,468.3 Million in 2024 and is projected to reach USD 3,822.3 Million by 2033, with a CAGR of 10% during the 2025-2033 forecast period. The market growth is driven by increasing health awareness about plant-based diets, a rising vegan population, and improved accessibility of vegan products. For more detailed insights, visit the India Vegan Food Market report.

STUDY ASSUMPTION YEARS

➤ Base Year:…

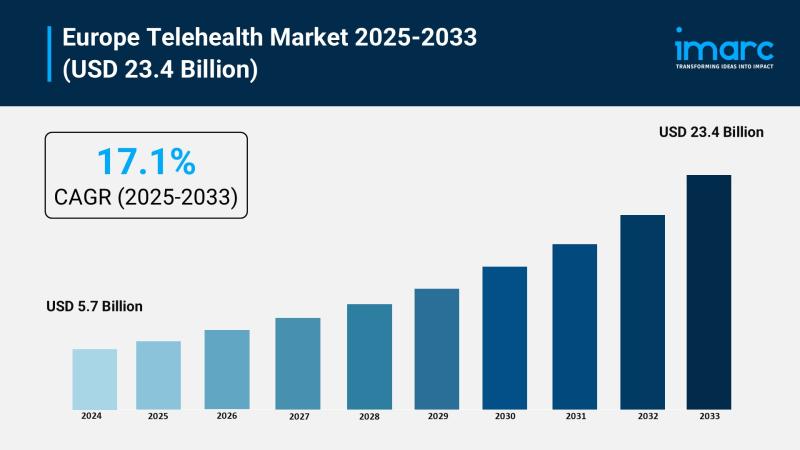

Europe telehealth market to grow from USD 5.7 Billion in 2024 to USD 23.4 Billio …

Market Overview

The Europe telehealth market was valued at USD 5.7 Billion in 2024 and is projected to reach USD 23.4 Billion by 2033, exhibiting a CAGR of 17.1% during the forecast period from 2025 to 2033. This growth is driven by rising demand for remote healthcare services, expanding aging populations, continuous innovations in digital health technologies, higher adoption of smartphones and wearables, government support, and the need for cost-effective healthcare…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…