Press release

Inline Foil Punch and Seal Machines Market Set to Reach USD 3.8 Billion by 2035 as Automation, Precision, and New Entrants Drive Growth

The global Inline Foil Punch and Seal Machines Market is poised for steady expansion, climbing from USD 2.9 billion in 2025 to USD 3.8 billion by 2035. This growth reflects a 31% overall increase over the decade, advancing at a CAGR of 2.7%. With demand rising for precision packaging in pharmaceuticals, FMCG, dairy, and nutraceutical industries, the market is shaping up as a battleground where established manufacturers refine their portfolios while new entrants disrupt with compact, cost-optimized, and digital-ready solutions.Quick Market Overview

In 2025, the market is valued at USD 2.9 billion and is projected to cross USD 3.8 billion by 2035. The rotary punching segment dominates with a 47.2% share, favored for its speed and precision. Regionally, Asia-Pacific leads adoption, with Japan emerging as the fastest-growing market at a CAGR of 3.1%. Among the companies driving innovation are IMS / Imsmachines, NK Industries Limited, Pillar Technologies, Inc., For-Bro Engineers (ForBropack), Mahalaxmi Machines, and Shree Vishvakarma Industries.

Request Your Sample Now: https://www.futuremarketinsights.com/reports/sample/rep-gb-22917

Two-Phase Growth Journey

Between 2025 and 2030, the industry is expected to add USD 0.4 billion, accounting for nearly 44.4% of the decade's growth. This stage will be defined by high-speed inline packaging systems and integrated sealing-punching solutions that minimize downtime. Global leaders like IMS and Pillar Technologies are enhancing modular systems that serve pharmaceutical and nutraceutical lines where sterility and consistency remain non-negotiable.

The second phase, from 2030 to 2035, will see a sharper momentum, adding USD 0.5 billion, or 55.6% of the total decade's growth. At this stage, adoption will accelerate in digitally controlled packaging lines equipped with vision inspection, foil traceability, and smart diagnostics. Sustainability mandates will also push companies toward precision-based foil application to reduce wastage while ensuring airtight seals.

Historical Trajectory

From 2020 to 2024, the market grew from USD 2.5 billion to USD 2.8 billion, driven largely by hardware-centric adoption in pharmaceuticals, food, and nutraceuticals. Inline systems ensured sealing accuracy and hygiene compliance. During this time, machine manufacturers controlled nearly 70% of revenue, with IMS, NK Industries, and Pillar Technologies leading the charge. Their edge came from format flexibility, thermal consistency, and inline automation integration, catering to blister packs, cap sealing, and container foil applications.

Service-based models contributed less than 10% of revenue in that phase, but this dynamic is changing. By 2035, IoT-enabled features, predictive maintenance, and digital service platforms are expected to make up over 40% of total revenue. This shift is attracting new entrants who offer cloud dashboards, SCADA compatibility, and recipe-driven controls, reshaping the competitive balance.

Why the Market is Growing

The market's expansion stems from the global push for automation, hygiene, and tamper-proof packaging. Inline foil punch and seal machines deliver accurate punching and hermetic sealing, extending shelf life and ensuring product integrity. The boom in single-serve formats in dairy, nutraceuticals, and ready-to-eat food further accelerates adoption.

Advancements in servo-driven and PLC-controlled machines allow consistent pressure and precision at high speeds. Vision inspection systems and IoT-based monitoring enhance operational efficiency while reducing errors. Industries such as pharma, dairy, and personal care increasingly depend on these machines to meet compliance, scale production, and maintain hygienic standards.

Segmental Analysis

The rotary punching segment is expected to capture 47.2% of the market in 2025 due to its continuous-motion operation, faster cycle times, and precision alignment. These features are indispensable in high-volume pharmaceutical blister packaging. Innovations in servo-driven rotary units are extending flexibility to custom foil geometries, keeping GMP and FDA compliance in check.

The pharmaceutical sector dominates the end-use category with a 49.2% share in 2025. With rising demand for tamper-evident blister packs and dosage compliance, pharma packaging requires precise sealing and traceability features. Inline foil punch and seal machines allow real-time cavity sealing, embossing, and batch coding, minimizing human error while boosting throughput.

On the material side, aluminum foil holds a commanding 42.1% share in 2025, valued for its superior barrier properties against moisture, oxygen, and microbes. Its compatibility with embossing and anti-counterfeiting technologies strengthens its role in regulated packaging lines.

In terms of speed, medium-speed machines (100-300 cycles/min) dominate with 47.3% share in 2025. They balance cost efficiency with productivity, making them attractive for mid-scale pharma and dairy operations.

Regional and Country-Level Insights

Japan is the fastest-growing market, expanding at 3.1% CAGR. Its adoption is powered by compact, cleanroom-compatible systems used in clinical packaging, anti-microbial sachets, and high-end foodservice packs. Local OEMs are integrating machine vision for defect detection, setting global benchmarks for precision.

Germany follows with a 2.9% CAGR, focusing on regulatory-driven precision packaging for pharmaceuticals and baby food. German OEMs are also advancing recyclable foil compatibility and predictive maintenance features.

India, with a 2.8% CAGR, is seeing robust demand in generic pharma, ayurvedic packaging, and dairy cooperatives. Domestic players such as Mahalaxmi Machines and Shree Vishvakarma Industries are making strides with modular, cost-optimized machines tailored for diverse SKUs.

The United States, growing at 1.2% CAGR, continues to adopt foil punch systems for dairy cups, nutraceutical sachets, and condiment packs, while upgrades remain concentrated among larger enterprises.

China, at 1.5% CAGR, shows demand from traditional medicine, herbal supplements, and meal kit brands, though adoption remains fragmented.

The United Kingdom, with a CAGR of 1.1%, faces slower adoption due to high replacement costs, but large co-packers and pharma OEMs are embracing precision sealing stations.

Get the Report Brochure Now: https://www.futuremarketinsights.com/reports/brochure/rep-gb-22917

Competitive Landscape

The market is moderately fragmented with global leaders, regional champions, and specialized firms competing.

Global leaders such as IMS / Imsmachines, NK Industries Limited, and Pillar Technologies maintain a stronghold with precision punching, advanced foil feeding, and high-speed FFS compatibility. Their strategies now focus on hygienic design, modular PLC control, and remote diagnostics.

Emerging companies like For-Bro Engineers (ForBropack), Mahalaxmi Machines, and Shree Vishvakarma Industries are gaining share by offering compact, cost-effective, and customizable inline-ready designs. Their strength lies in catering to mid-cap and SME producers that require efficiency without the high capital costs.

Regional specialists are thriving in spice caps, nutritional packs, and container sealing niches, especially in India and Southeast Asia. Their adaptability and strong customer support during format changeovers make them valuable partners in local markets.

Outlook for the Future

By 2035, the Inline Foil Punch and Seal Machines Market will not just be about hardware performance but about digital intelligence and sustainability. Established players are pivoting to hybrid models with IoT-enabled controls, SCADA compatibility, and predictive diagnostics, while new entrants are innovating in compactness, affordability, and compliance readiness.

The convergence of automation, safety, and sustainability is redefining packaging lines across industries. As demand for tamper-proof, hygienic, and smart packaging solutions grows, inline foil punch and seal machines will remain indispensable for ensuring integrity, efficiency, and compliance.

Explore Similar Insights

Inline Quality Control Sensors Market https://www.futuremarketinsights.com/reports/inline-quality-control-sensors-market

Vertical Inline Pumps Market https://www.futuremarketinsights.com/reports/vertical-inline-pumps-market

Foil Laminates Market https://www.futuremarketinsights.com/reports/foil-laminates-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Inline Foil Punch and Seal Machines Market Set to Reach USD 3.8 Billion by 2035 as Automation, Precision, and New Entrants Drive Growth here

News-ID: 4177912 • Views: …

More Releases from Future Market Insights

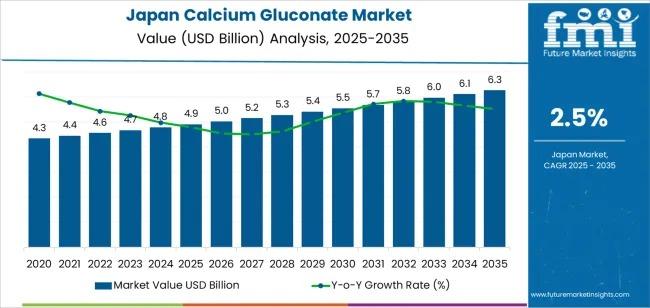

Japan's Calcium Gluconate Demand to Reach USD 6.3 Billion by 2035 Driven by Prev …

The demand for calcium gluconate in Japan is projected to rise from USD 4.9 billion in 2025 to USD 6.3 billion by 2035, registering a compound annual growth rate (CAGR) of 2.5%. Calcium gluconate, a calcium salt, is widely used across pharmaceutical and food industries, from intravenous treatments for calcium deficiencies to fortifying foods and beverages.

The growth is primarily driven by the increasing prevalence of calcium-related deficiencies and the expanding…

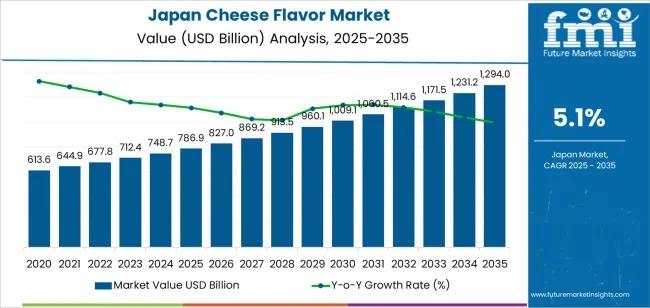

Japan's Cheese Flavor Demand to Surpass USD 1.29 Trillion by 2035, Driven by Sna …

The demand for cheese flavor in Japan is projected to expand from USD 786.9 billion in 2025 to USD 1,293.8 billion by 2035, advancing at a steady 5.1% CAGR. Growth is anchored in the rising use of cheese flavor systems across snack foods, processed meals, baked goods and seasoning blends-segments where authentic taste delivery and differentiation continue to shape product development strategies nationwide.

Japan's food manufacturing ecosystem is integrating more sophisticated…

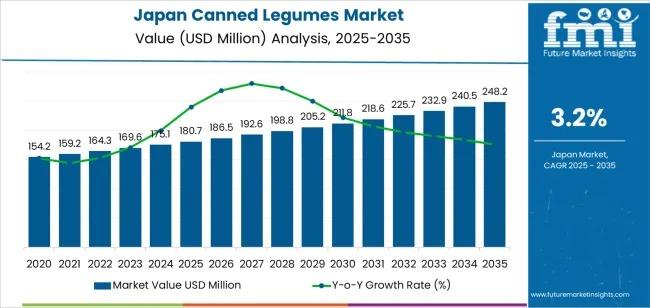

Japan's Canned Legumes Demand Set for Steady Growth, Expected to Reach USD 248.2 …

Japan's canned legumes demand is valued at USD 180.7 million in 2025 and is projected to reach USD 248.2 million by 2035, expanding at a 3.2% CAGR. Growth is driven by rising adoption of plant-based proteins, broader use of ready-to-cook ingredients, and strong preference for shelf-stable foods among urban and small households.

Consumption continues to increase as households incorporate canned chickpeas, beans, peas, and mixed legumes into salads, curries, simmered dishes,…

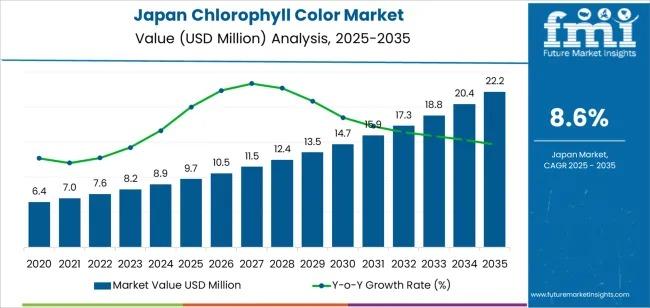

Japan's Demand for Chlorophyll Color Set to Reach USD 22.2 Billion by 2035 as Cl …

Japan's chlorophyll color industry is entering a decade of accelerated transformation, supported by stringent clean-label regulations, rising consumer scrutiny, and rapid reformulation activity across food and beverage categories. The market is valued at USD 9.7 billion in 2025 and is forecast to reach USD 22.2 billion by 2035, expanding at a strong 8.6% CAGR, underscoring its transition from niche natural colorant to a mainstream formulation priority for manufacturers nationwide.

This surge…

More Releases for Inline

Inline Density Sensors Market Research Report

Global Inline Density Sensors Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031

According to our (Global Info Research) latest study, the global Inline Density Sensors market size was valued at US$ 298 million in 2024 and is forecast to a readjusted size of USD 447 million by 2031 with a CAGR of 6.1% during review period.

Global Info Research's report offers key insights into the recent developments…

Inline Moisture Sensors Latest Market Report 2025

Global Info Research announces the release of the report "Global Inline Moisture Sensors Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets.…

Why Should One Get An Inline Checkweigher System?

An inline checkweigher system [https://www.sgcheckweigher.com/checkweigher-1/] is a crucial investment for any production line due to its ability to provide real-time, accurate weight measurements of products as they move through the line. inline checkweigher systems [https://www.sgcheckweigher.com/checkweigher-1/] are designed to check the weight of your products directly in your production lines without having to stop them. They present many advantages for the control of prepackaged goods, missing products and tolerance checks. Here…

Inline Viscosity Sensors Market 2021 | Detailed Report

According to Market Study Report, Inline Viscosity Sensors Market provides a comprehensive analysis of the Inline Viscosity Sensors Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC, Tables and Figures) of Inline Viscosity Sensors Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5048562

The report provides a…

Inline AOI Systems Market - Growth of Inline Aoi System Market Is Boosted By Inc …

Automated optical inspection (AOI) is a process of visual inspection which is operated automatically to detect different manufacturing defect such as catastrophic failure and quality defect. This technology is adopting by different types of manufacturer such as printed circuit board manufacturing, liquid - crystal display (LCD) manufacturing, transistor manufacturing, others. Moreover, AOI systems has been segmented in two types such as desktop AOI and Inline AOI systems. Inline AOI…

New ParticleTrackTM E25 provides accessible inline characterization

A new inline characterization tool from METTLER TOLEDO provides a simple, effective method for robust in situ aqueous chemistry particle system tracking, helping to enhance optimization and reduce quality control costs in labs and production environments across a wide range of industries.

METTLER TOLEDO is pleased to announce the launch of its new inline particle system characterization tool ParticleTrackTM E25. Modifying focused beam reflectance technology (FBRM®) for use in settings where…