Press release

Pavers Block Manufacturing Cost Report 2025: Plant Setup Economics and Financial Outlook

Paver blocks, also known as paving blocks, are precast concrete units used for creating durable and aesthetically appealing surfaces in outdoor spaces such as driveways, walkways, parking areas, and landscapes. They are available in various shapes, sizes, colors, and patterns, offering both functional strength and decorative appeal. Their interlocking design provides high load-bearing capacity, resistance to wear, and ease of maintenance, making them a preferred alternative to traditional asphalt or concrete surfaces.Setting up a paver block manufacturing plant involves selecting a suitable location, procuring raw materials such as cement, sand, and aggregates, and installing block-making machinery with curing facilities. Efficient layout planning, quality control measures, and proper workforce training ensure consistent production standards. With moderate capital investment, scalable capacity, and growing demand in urban infrastructure, a paver block plant offers significant business potential.

IMARC Group's "Pavers Block Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as pavers block manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/pavers-block-manufacturing-plant-project-report/requestsample

Pavers Block Industry Outlook 2025:

The paver block industry outlook for 2025 remains highly positive, driven by rapid urbanization, smart city initiatives, and growing infrastructure development across residential, commercial, and industrial sectors. Increasing preference for durable, eco-friendly, and visually appealing paving solutions is fueling demand, supported by government projects in roadways, housing, and public spaces. Advancements in manufacturing technology and the use of sustainable materials are further enhancing product quality and design versatility. With rising construction activities in emerging economies, the paver block industry is projected to experience steady growth, offering strong opportunities for manufacturers and investors.

Key Insights for Pavers Block Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Pavers Block Plant:

• Land and Site Development - Cost of purchasing or leasing land, leveling, and preparing the site.

• Machinery and Equipment - Block-making machines, mixers, molds, curing chambers, and handling tools.

• Raw Materials - Initial procurement of cement, sand, aggregates, pigments, and additives.

• Construction and Infrastructure - Plant building, storage areas, power supply, and water facilities.

• Labor and Training - Skilled and unskilled workforce expenses, along with training costs.

• Utilities and Power Supply - Electricity, water, and fuel requirements for production.

• Working Capital - Initial funds for raw material purchase, wages, and operating expenses.

• Transportation and Logistics - Costs of moving raw materials and finished products.

• Quality Control and Testing - Equipment and processes to ensure product standards.

• Licensing and Compliance - Government approvals, certifications, and legal documentation.

Economic Trends Influencing Pavers Block Plant Setup Costs 2025:

• Rising Construction Demand - Increased infrastructure projects and urban housing drive higher raw material and labor costs.

• Fluctuating Cement and Aggregate Prices - Volatility in raw material markets directly impacts production expenses.

• Energy and Fuel Costs - Growing electricity and fuel prices raise operational and machinery running costs.

• Technological Advancements - Adoption of automated block-making machines requires higher upfront investment but reduces long-term labor costs.

• Government Policies and Regulations - Environmental compliance, taxation, and licensing fees influence overall setup costs.

• Labor Market Trends - Skilled labor shortages and wage inflation affect workforce-related expenses.

• Financing and Interest Rates - Availability of credit and lending rates shape capital investment feasibility.

• Sustainability Initiatives - Increasing demand for eco-friendly materials may lead to higher procurement and certification costs.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8489&flag=C

Challenges and Considerations for Investors in Pavers Block Plant Projects:

• High Initial Capital Investment - Significant costs for land, machinery, and infrastructure setup.

• Raw Material Price Volatility - Dependence on cement, sand, and aggregates exposes operations to fluctuating costs.

• Quality Control Requirements - Maintaining consistent strength, durability, and design standards demands strict testing and monitoring.

• Competition and Market Saturation - Local manufacturers and unorganized players may create pricing pressure.

• Labor Management - Availability of skilled workforce and the need for continuous training can be challenging.

• Regulatory Compliance - Adherence to environmental norms, licensing, and safety regulations is essential.

• Logistics and Distribution - Transporting heavy blocks requires efficient supply chain planning and cost management.

• Technology Upgradation - Keeping pace with automated systems and innovative designs involves recurring investments.

Conclusion:

In conclusion, the paver block industry presents strong growth prospects, supported by urban infrastructure expansion, sustainable construction practices, and increasing demand for durable paving solutions. While setting up a plant offers attractive returns, it requires careful consideration of cost components, market dynamics, and regulatory frameworks. Investors must balance capital investment with technological adoption, quality control, and efficient supply chain management to remain competitive. With strategic planning and a focus on innovation, paver block manufacturing can be a sustainable and profitable venture in the evolving construction materials sector.

Buy Now: https://www.imarcgroup.com/checkout?id=8489&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pavers Block Manufacturing Cost Report 2025: Plant Setup Economics and Financial Outlook here

News-ID: 4179378 • Views: …

More Releases from IMARC Group

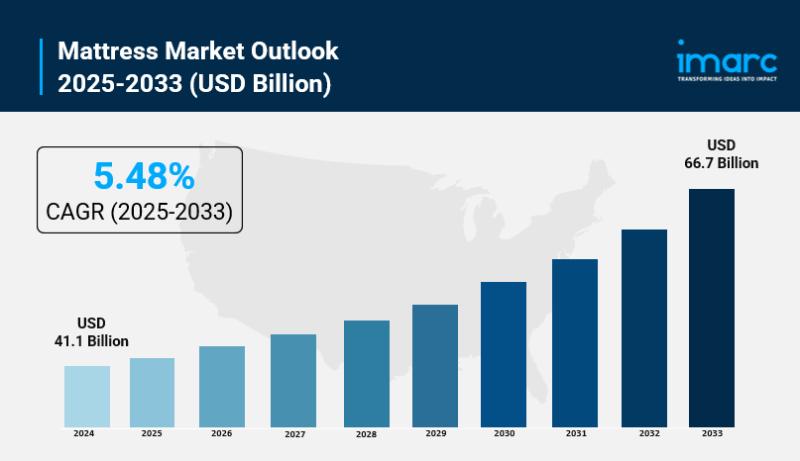

Mattress Market Size, Share, Global Industry Overview, Growth Factors and Foreca …

IMARC Group, a leading market research company, has recently releases a report titled "Mattress Market Report by Product (Innerspring Mattresses, Memory Foam Mattresses, Latex Mattresses, and Others), Distribution Channel (Online Distribution, Offline Distribution), Size (Twin or Single Size, Twin XL Size, Full or Double Size, Queen Size, King Size Mattress, and Others), Application (Domestic, Commercial), and Region 2025-2033." The study provides a detailed analysis of the industry, including the global…

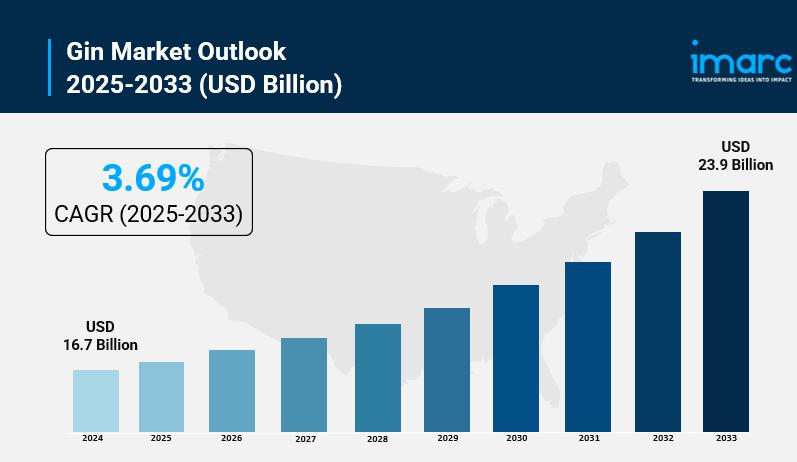

Gin Market Size, Share, Global Industry Trends, Analysis and Forecast 2025-2033

IMARC Group, a leading market research company, has recently released a report titled "Gin Market Report by Type (London Dry Gin, Old Tom Gin, Plymouth Gin, and Others), Price Point (Standard, Premium, Luxury), Distribution Channel (On-trade, Off-trade), and Region 2025-2033." The study provides a detailed analysis of the industry, including the global gin market share, size, trends, and growth forecast. The report also includes competitor and regional analysis and highlights…

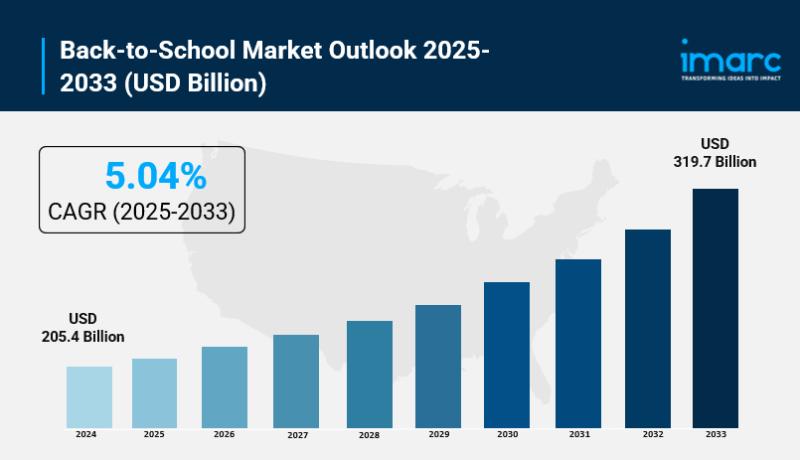

Back-to-School Market Size, Share, Industry Overview, Latest Trends and Forecast …

IMARC Group, a leading market research company, has recently released a report titled "Back-to-School Market Report by Product Type (Clothing and Accessories, Stationery Supplies, Electronics), Distribution Channel (Online, Offline), and Region 2025-2033." The study provides a detailed analysis of the industry, including the global back-to-school market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Back-to-School Market Highlights:

• Back-to-School…

Tater Tots Manufacturing Plant Cost Report 2025: Setup Details, Business Plan an …

Introduction

Tater tots are small, cylindrical pieces of grated potatoes that are seasoned, lightly fried, and often baked to create a crispy, golden exterior with a soft, fluffy interior. Originating in the United States in the 1950s, they were initially developed as a way to utilize leftover potato scraps from French fry production. Over time, tater tots have become a popular comfort food and side dish, celebrated for their convenience, versatility,…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…