Press release

Global Textile Machine Lubricants Market Projected to Reach USD 2.1 Billion by 2035 Driven by Innovation and Growing Demand in Textile Industry

The Textile Machine Lubricants Market is on a robust growth trajectory, with market valuation expected to increase from USD 1.3 billion in 2025 to USD 2.1 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.0%. This expansion is being propelled by the rising adoption of advanced lubrication solutions across textile manufacturing processes, driven by the need for higher efficiency, reduced downtime, and extended equipment lifecycles. Established players and emerging manufacturers alike are investing in innovative formulations and technologies to meet the evolving requirements of modern textile machinery.Market Growth Drivers

The textile industry is undergoing a transformative phase, with automation and precision engineering taking center stage. Advanced spinning, weaving, knitting, and finishing machines require lubricants that reduce friction, heat generation, and wear, ensuring smooth and reliable operations. This focus on precision has underscored the importance of specialized lubricants, which directly impact the quality of fabrics and consistency of output. As textile manufacturers modernize facilities and expand production capacities, the demand for effective lubrication solutions continues to grow.

Full Market Report available for delivery. For purchase or customization, please request here:

https://www.futuremarketinsights.com/reports/sample/rep-gb-7737

Sustainability is emerging as a key consideration in the industry. Manufacturers are increasingly exploring eco-friendly and high-performance lubricant formulations, including bio-based and synthetic blends, to balance performance with environmental responsibility. These innovative solutions not only support operational efficiency but also contribute to cost savings and reduced environmental impact, creating a favorable outlook for the market over the next decade.

Dominance of Mineral Oil-Based Lubricants

The Mineral Oil-Based segment is projected to lead the market, accounting for 57.6% of revenue in 2025. This segment's stronghold is attributed to the cost-effectiveness, wide availability, and proven performance of mineral oil lubricants. Their compatibility with diverse textile machinery and ability to maintain stable viscosity under varying temperature and load conditions have cemented their position as a preferred choice for spinning, weaving, and knitting operations.

Mineral oil-based lubricants benefit from well-established supply chains and affordability, making them attractive for both small and large-scale manufacturers. While the market is witnessing increasing interest in synthetic and bio-based alternatives, mineral oil remains the dominant option due to its reliability and broad acceptance across the textile sector.

Spinning Machines Drive Machinery Segment Growth

Among machine types, Spinning Machines account for the largest share, projected at 41.8% of market revenue in 2025. Spinning operations form the backbone of textile production, where machine efficiency directly influences output quality and volume. Lubricants play a crucial role in minimizing friction in spindles, bearings, and gears, all of which operate under high-speed conditions.

The growth of this segment is supported by the adoption of advanced spinning technologies that demand reliable lubrication to maintain precision and prevent downtime. As global textile demand rises, the importance of high-performance lubricants in spinning machines becomes even more critical, ensuring smooth operations, reducing maintenance costs, and extending machine lifespans.

Technological Advancements and Innovations

Manufacturers of textile machine lubricants are focusing on research and development to deliver innovative products that cater to diverse machinery needs. Given the variety of textile equipment, a single lubricant cannot serve all applications, driving opportunities for product differentiation. Companies are developing specialized lubricants that withstand extreme operating conditions, resist chemical degradation, and remain non-staining to fabrics, meeting both operational and quality requirements.

Vertical integration is another emerging trend. Some textile machine manufacturers are supplying lubricants as part of their after-sales service offerings, strengthening client relationships and creating new revenue streams. Strategic collaborations, joint ventures, and capacity expansions are enabling both established and new players to expand market reach and capitalize on growing demand.

Get the Report Brochure Now:

https://www.futuremarketinsights.com/reports/brochure/rep-gb-7737

Regional Market Insights

The Asia-Pacific region is anticipated to hold a significant market share due to the concentration of large-scale and SME textile manufacturers. The region's expanding production capabilities and adoption of modern machinery drive strong demand for reliable lubrication solutions. North America follows closely, with manufacturers emphasizing uninterrupted production and efficiency. Europe maintains a vital position, supported by high-density textile manufacturing hubs.

Emerging markets in the Middle East and Africa are also gaining traction, as investments in textile infrastructure increase. Latin America is expected to experience modest growth, primarily driven by imports of textiles from major manufacturing countries such as China and the USA. Country-specific growth highlights include China with a 6.8% CAGR, India at 6.3%, and Germany at 5.8%, illustrating strong momentum across both developing and developed markets.

Key Players Shaping the Market

The global textile machine lubricants market features leading players such as Kluber Lubrication (Freudenberg Group), Nye Lubricants, Total S.A., The Chemours Company, Vickers Oils, Bruckner Textile Machinery, Eni Oil Products, Matrix Specialty Lubricants, Carl Bechem GmbH, Eldons Lubricants Industry, Caltex, and MORESCO Corporation. These companies are actively investing in product innovation, expanding production capacity, and entering new markets to strengthen their competitive positioning.

Emerging manufacturers are leveraging cutting-edge technology and sustainable formulations to differentiate themselves. Their focus on efficiency, eco-friendly solutions, and cost-effective alternatives is enhancing competition while driving overall market growth. Collaborative ventures and strategic alliances are also helping companies to optimize distribution networks and meet evolving customer needs globally.

Future Outlook

The Textile Machine Lubricants Market is expected to maintain a CAGR of 5.0% through 2035, supported by automation, rising textile production, and increasing investments in high-performance machinery. Innovations in lubricant formulations, sustainable practices, and targeted solutions for specialized machinery will continue to shape the market. With global textile demand on the rise and manufacturers prioritizing efficiency, quality, and sustainability, the role of textile machine lubricants will remain critical, reinforcing their position as an indispensable component of modern textile production.

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Textile Machine Lubricants Market Projected to Reach USD 2.1 Billion by 2035 Driven by Innovation and Growing Demand in Textile Industry here

News-ID: 4185100 • Views: …

More Releases from Future Market Insights

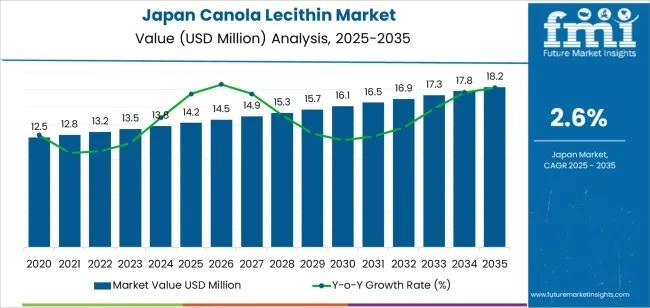

Japan Canola Lecithin Market to Reach USD 18.2 Million by 2035 Driven by Food, P …

Japan's canola lecithin market is entering a phase of steady expansion, supported by rising consumer demand for natural, clean-label emulsifiers and the growing use of plant-based ingredients across food, pharmaceutical, and cosmetics applications. Market projections show demand increasing from USD 14.2 million in 2025 to USD 18.2 million by 2035, driven by a shift toward healthier formulations and sustained growth in processed food and nutraceutical categories.

Canola lecithin continues to gain…

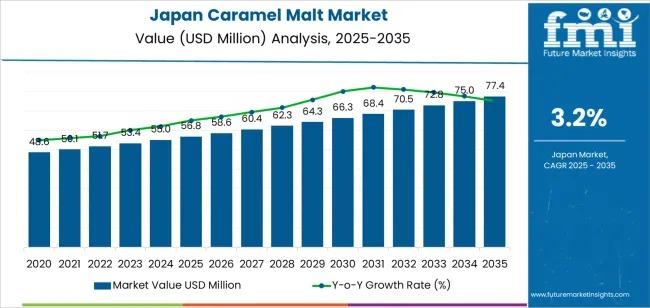

Japan Caramel Malt Market to Reach USD 77.4 Million by 2035 Driven by Craft Brew …

Japan's caramel malt demand is experiencing consistent growth as breweries-both large-scale producers and craft operations-continue to rely on caramel malt for sweetness, foam stability, and refined roasted notes essential to Japan's evolving beer landscape. The market is valued at USD 56.8 million in 2025 and is projected to reach USD 77.4 million by 2035, driven by expanding flavor diversification and the prominence of malt-balanced beer styles across the country.

Light-colour caramel…

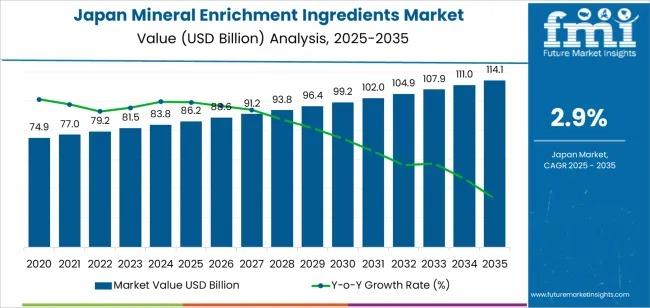

Japan Mineral Enrichment Ingredients Market to Reach USD 114.1 Billion by 2035 D …

The demand for mineral enrichment ingredients in Japan is set to rise from USD 86.2 billion in 2025 to USD 114.1 billion by 2035, expanding at a consistent CAGR of 2.9%. This growth reflects Japan's long-standing emphasis on nutrition enhancement, healthy aging, and expanded use of fortified ingredients across food, beverage, and supplement categories. With consumers seeking functional, nutrient-dense foods, ingredients such as calcium, iron, magnesium, zinc, and trace minerals…

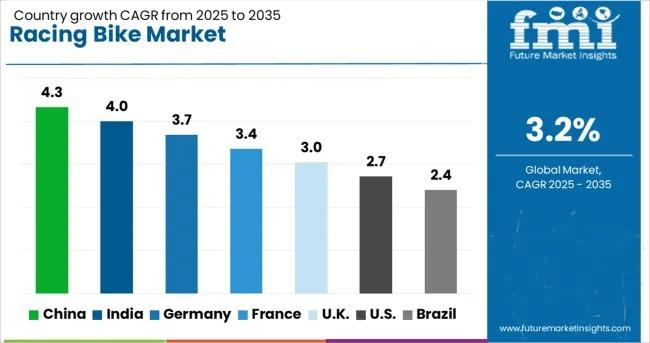

Global Racing Bike Market to Reach USD 9.9 Billion by 2035, Driven by Performanc …

The global Racing Bike Market is entering a phase of steady, technology-led expansion, underpinned by rising participation in competitive cycling, increasing professional sponsorships, and accelerating innovation in lightweight bicycle engineering. The market is valued at USD 7.2 billion in 2025 and is forecast to reach USD 9.9 billion by 2035, expanding at a compound annual growth rate (CAGR) of 3.2% over the ten-year period.

Market fundamentals remain strong as manufacturers align…

More Releases for Lubricants

Indonesia Lubricant Market Expected to Surpass USD 4.36 Billion Mark by 2031 | M …

USA, New Jersey: Verified Market Research reports that the global IIndonesia Lubricant Market size was valued at USD 2.46 Billion in 2024 and is projected to reach USD 4.36 Billion by 2032, growing at a CAGR of 7.4% from 2025 to 2032. This steady growth is driven by increasing environmental regulations, rising awareness of pollution control, and expanding applications in industries such as manufacturing, energy, and healthcare.

Indonesia Lubricant Market -…

India Industrial Lubricants Market Drivers: Apar Industries, Valvoline Cummins, …

The India industrial lubricants market is poised for significant expansion, with its valuation anticipated to climb from an estimated USD 59.4 billion in 2025 to a remarkable USD 86.8 billion by 2035, exhibiting a Compound Annual Growth Rate (CAGR) of 3.8%. This impressive trajectory is fundamentally driven by increased domestic manufacturing, substantial infrastructure investment, and rising awareness of predictive maintenance practices across key industries such as steel, cement, textiles, and…

Biodegradable Lubricants Will Support Demand for Agricultural Lubricants

The material known as a lubricant is used to lessen friction or abrasion between two surfaces that are in touch with one another. It is accessible in solid, liquid, and gaseous states and aids in the removal of heat and the transition of power.

Semisolid versions of them can also be discovered. Grease is one of the most typical types of lubricants in a semisolid form. To boost productivity, lubricants are…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricants are essential for modern life. Thanks to the sophisticated oil and grease integration, car engines and transmissions run smoothly.

Lubricants are great fluids. Irrespective of weather conditions, engine oil must operate reliably in the temperature range of 40°C to 250°C or higher (piston ring upper temperature). It must also withstand pressures of 105 to 109 Pascals and contaminants such as metal particles and soot.

Lubricants perform the main functions of…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricants are essential in modern life. Car machines and gearboxes run smoothly through the integration of advanced oils and fats. Lubricants are remarkable liquids. Regardless of the weather conditions, the engine oil must operate reliably at temperatures of 40 ° C to above 250 ° C - the temperature near the upper piston ring. It also has to deal with presses between 105 and 109 Pascacakes as well as contaminants,…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricating oils are essential to modern life. Automotive engines and gearboxes run smoothly due to the sophisticated oil and grease integration. Lubricating oil is an amazing fluid. Regardless of weather conditions, engine oil should operate stably at temperatures in the range of 250 ° C and above (the temperature near the upper piston ring) at 40 ° C. It also deals with pressures between 105 and 109 Pascals, as well…