Press release

Ammonium Sulphate Production Cost Analysis 2025: Profitability Analysis

Ammonium sulphate ((NH4)2SO4) is an inorganic salt primarily used as a nitrogen-based fertilizer in agriculture. It provides essential nutrients that promote plant growth and improve soil nitrogen content. Additionally, it is used in water treatment, pharmaceuticals, textiles, and food processing as a stabilizing or buffering agent. Known for its high solubility and compatibility with alkaline soils, ammonium sulphate remains one of the most reliable and cost-effective nitrogen fertilizers worldwide.A manufacturing plant requires raw materials such as ammonia and sulfuric acid, along with reactors, crystallizers, dryers, and packaging units. Infrastructure setup, skilled labor, utilities, quality control systems, and compliance with environmental and safety standards add to the overall investment. Efficient process control is key to maintaining product purity and minimizing waste.

Request for a Sample Report: https://www.imarcgroup.com/ammonium-sulphate-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Ammonium Sulphate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an ammonium sulphate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a ammonium sulphate production plant successful unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as ammonium sulphate production plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Ammonium Sulphate Industry Outlook 2025:

The ammonium sulphate industry is projected to grow steadily by 2025, driven by rising global fertilizer demand, expanding agricultural productivity, and increasing adoption of nitrogen-based fertilizers. Technological advancements in production, government support for sustainable farming, and strong demand from emerging markets are expected to enhance industry growth and profitability.

Key Insights for Ammonium Sulphate Production Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=8804&flag=C

Key Cost Components of Setting Up an Ammonium Sulphate Plant:

• Raw Materials: Volatility in sodium bisulfite, sulfur dioxide, and sodium hydroxide prices due to global supply-demand dynamics, energy costs, and quality requirements.

• Machinery & Equipment: Rising costs for reactors, drying units, cooling systems, packaging machines, and safety equipment due to inflation, supply chain disruptions, and demand for automated production systems.

• Infrastructure & Utilities: Escalating construction material costs, higher electricity, water, and gas tariffs, and investment in environmental compliance and safety-compliant facilities.

• Labor & Staffing: Increasing wages for chemical engineers, skilled operators, and quality control personnel; shortage of trained workforce in reactive chemical processing adding to staffing costs.

• Licenses & Regulatory Compliance: Growing expenses for industrial permits, environmental approvals, safety certifications, and adherence to hazardous chemical handling standards.

• Operational & Miscellaneous Costs: Rising transportation, packaging, maintenance, insurance, and contingency expenses due to chemical handling risks, logistics challenges, and inflation.

Economic Trends Influencing Ammonium Sulphate Plant Setup Costs 2025:

• Raw Material Price Volatility: Fluctuating costs of sodium bisulfite, sulfur dioxide, and sodium hydroxide due to global supply-demand imbalances and energy market changes.

• Inflationary Pressures: Rising prices of machinery, construction materials, and utilities increasing overall capital expenditure.

• Supply Chain Disruptions: Delays and higher expenses in importing specialized chemical processing and packaging equipment due to global logistics challenges.

• Labor Market Dynamics: Shortage of skilled chemical engineers, operators, and quality control staff leading to higher wages and training costs.

• Energy and Utility Costs: Increasing electricity, water, and fuel tariffs affecting operational efficiency and infrastructure investments.

• Regulatory Changes: Stricter environmental, safety, and hazardous chemical handling regulations requiring additional compliance and investment.

• Growing Industrial Demand: Rising applications in food preservation, water treatment, pharmaceuticals, and textiles driving higher production capacity requirements.

• Technological Advancements: Investment in automated, precise, and efficient production technologies increasing initial setup costs but improving yield, safety, and long-term profitability.

Challenges and Considerations for Investors in Ammonium Sulphate Plant Projects:

• Raw Material Supply Risks: Dependence on consistent availability of sodium bisulfite, sulfur dioxide, and sodium hydroxide; vulnerability to global price fluctuations and supply constraints.

• Price Volatility: Frequent changes in raw material, energy, and transportation costs affecting profitability and return on investment.

• High Capital Investment: Significant expenditure on reactors, drying units, cooling systems, packaging machinery, and safety-compliant infrastructure.

• Skilled Labor Shortage: Difficulty in recruiting and retaining trained chemical engineers, operators, and quality control personnel.

• Regulatory Compliance: Costs and time involved in obtaining environmental permits, hazardous chemical handling certifications, and adherence to local and international standards.

• Energy and Utility Dependence: Rising electricity, water, and fuel costs impacting operational efficiency and margins.

• Safety and Environmental Risks: Handling reactive chemicals requires strict safety protocols, proper storage, and emergency preparedness, increasing operational costs.

• Market Competition: Competition from established chemical manufacturers necessitating efficient production, quality assurance, and market differentiation.

• Logistics and Distribution Challenges: Safe transportation of raw materials and finished products adds complexity and cost.

Buy Now: https://www.imarcgroup.com/checkout?id=8804&method=1911

Conclusion:

Setting up an ammonium sulphate manufacturing plant involves significant investment across raw materials, machinery, infrastructure, skilled labor, regulatory compliance, and operational costs. Market volatility in sodium bisulfite, sulfur dioxide, and sodium hydroxide prices, growing demand in food preservation, water treatment, pharmaceuticals, and textiles, along with stringent environmental and safety regulations, significantly influence expenditure. Strategic planning, adoption of advanced automated production technologies, rigorous safety protocols, and efficient resource management are essential to optimize costs, ensure consistent product quality, and achieve sustainable profitability in the ammonium sulphate industry.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ammonium Sulphate Production Cost Analysis 2025: Profitability Analysis here

News-ID: 4209704 • Views: …

More Releases from IMARC Group

Mexico Microgrid Market Share, Size, In-Depth Analysis and Forecast 2025-2033

IMARC Group has recently released a new research study titled "Mexico Microgrid Market Size, Share, Trends and Forecast by Energy Source, Application, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Mexico Microgrid Market Overview

The Mexico microgrid market size reached USD 528.00 Million in 2024. Looking forward, IMARC Group expects the market to…

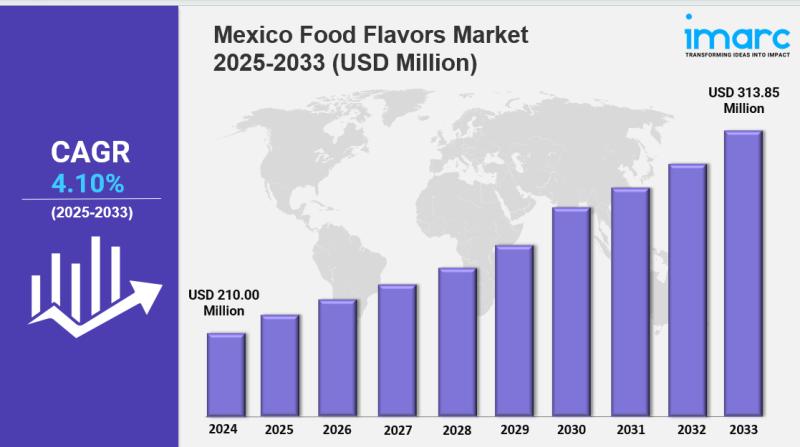

Mexico Food Flavors Market : Trends, Drivers, and Growth Opportunities 2025-2033

IMARC Group has recently released a new research study titled "Mexico Food Flavors Market Size, Share, Trends and Forecast by Type, Form, End User, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Mexico Food Flavors Market Overview

The Mexico food flavors market size reached USD 210.00 Million in 2024. Looking forward, IMARC Group…

UPVC and CPVC Pipe Manufacturing Plant Project Report 2025: Machinery and Raw Ma …

UPVC (Unplasticized Polyvinyl Chloride) pipes are rigid, durable pipes commonly used for cold-water distribution, drainage, and sewage systems. They offer excellent chemical resistance, corrosion-free performance, and long service life, making them ideal for plumbing and irrigation. CPVC (Chlorinated Polyvinyl Chloride) pipes are similar but chlorinated to withstand higher temperatures, making them suitable for hot-water supply and industrial fluid handling. Both types provide easy installation, cost-effectiveness, and reliability in residential, commercial,…

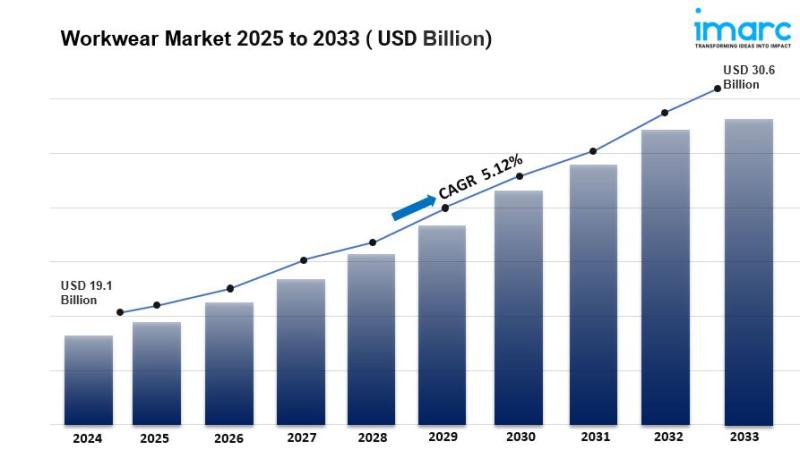

Workwear Market Size, Share, Growth And Trends Report 2025-2033

Workwear Market Overview:

The global Workwear Market size was valued at USD 19.08 Billion in 2024 and is projected to reach USD 30.60 Billion by 2033, registering a compound annual growth rate (CAGR) of 5.12% during the forecast period from 2025 to 2033. The Asia Pacific region dominates this market with a share of over 42.6%. Growth is driven by rising awareness of employee well-being and an increasing demand for comfortable…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…