Press release

Valsartan Manufacturing Plant Setup Report 2025: Cost Analysis and Investment Opportunities

Valsartan is a prescription medication belonging to the class of angiotensin II receptor blockers (ARBs). It is primarily used to treat high blood pressure (hypertension), heart failure, and to improve survival after a heart attack. By blocking the effects of angiotensin II, it relaxes blood vessels, reducing blood pressure and easing the heart's workload. Valsartan is widely prescribed due to its effectiveness and relatively low side-effect profile compared to older antihypertensive drugs.Establishing a Valsartan plant involves procuring active pharmaceutical ingredients (APIs), specialized reactors, and quality control labs. Key steps include regulatory approvals, GMP-compliant infrastructure, skilled workforce recruitment, and formulation development. Efficient supply chains for raw materials and robust quality assurance systems are critical for consistent production and market competitiveness.

IMARC Group's "Valsartan Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as valsartan manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/valsartan-manufacturing-plant-project-report/requestsample

Valsartan Industry Outlook 2025:

The Valsartan industry in 2025 is expected to experience steady growth driven by increasing awareness of cardiovascular health and a rising prevalence of hypertension and heart-related conditions. Innovation in formulations, such as combination therapies and patient-friendly dosage forms, is enhancing accessibility and adherence. Regulatory emphasis on quality and safety is shaping manufacturing practices, while expanding global healthcare infrastructure is creating new market opportunities. Overall, the industry is moving toward sustainable, efficient production with a focus on affordability, effectiveness, and meeting evolving patient needs worldwide.

Key Insights for Valsartan Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Valsartan Plant:

• Land and Building: Costs for acquiring land and constructing GMP-compliant manufacturing and laboratory facilities.

• Machinery and Equipment: Investment in reactors, filtration units, dryers, packaging machines, and analytical instruments.

• Raw Materials and APIs: Procurement of active pharmaceutical ingredients and excipients necessary for Valsartan production.

• Utilities and Infrastructure: Expenses for electricity, water, HVAC systems, waste management, and other essential services.

• Regulatory Compliance: Costs for obtaining approvals, certifications, and quality audits from health authorities.

• Labor and Training: Recruitment and training of skilled personnel for production, quality control, and operations.

• R&D and Formulation Development: Investment in product development, process optimization, and stability studies.

• Quality Assurance and Control: Expenses for in-house testing, analytical labs, and ongoing monitoring.

• Packaging and Labeling: Cost of packaging materials, labeling systems, and finished product storage.

• Contingency and Miscellaneous: Buffer for unforeseen expenses, maintenance, and operational setup challenges.

Economic Trends Influencing Valsartan Plant Setup Costs 2025:

• Raw Material Prices: Fluctuations in API and chemical costs impact overall production expenses.

• Energy and Utility Costs: Changes in electricity, water, and fuel prices affect operational budgets.

• Regulatory Changes: Stricter compliance standards can increase setup and operational costs.

• Labor Market Dynamics: Availability and wages of skilled workforce influence staffing expenses.

• Technological Advancements: Adoption of modern equipment may raise initial investment but improve efficiency.

• Global Supply Chain Shifts: Disruptions or changes in sourcing affect procurement costs.

• Inflation Trends: General economic inflation can increase construction, machinery, and material expenses.

• Healthcare Demand: Rising demand for cardiovascular drugs may drive investment in larger or more advanced facilities.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9715&flag=C

Challenges and Considerations for Investors in Valsartan Plant Projects:

• Regulatory Compliance: Meeting stringent global and local pharmaceutical regulations is complex and time-consuming.

• High Initial Investment: Setting up a GMP-compliant facility requires significant capital expenditure.

• Raw Material Dependence: Reliance on imported APIs or chemicals can cause supply chain vulnerabilities.

• Market Competition: Intense competition from generic manufacturers can affect profitability.

• Technological Requirements: Advanced equipment and skilled workforce are essential for quality production.

• Quality Assurance: Maintaining consistent product quality is critical to avoid recalls or regulatory penalties.

• Operational Risks: Production disruptions, equipment failures, or labor shortages can impact output.

• Patent and Intellectual Property Issues: Awareness of existing patents and licensing requirements is necessary.

Conclusion:

Investing in a Valsartan manufacturing plant presents significant opportunities due to growing demand for cardiovascular therapies and expanding healthcare needs. However, success depends on careful planning, adherence to stringent regulatory standards, robust quality control, and efficient supply chain management. Strategic investment in technology, skilled workforce, and process optimization can enhance competitiveness and profitability. While initial setup and operational challenges exist, a well-executed project can establish a sustainable presence in the pharmaceutical market and meet the rising global need for effective antihypertensive treatments.

Buy Now: https://www.imarcgroup.com/checkout?id=9715&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Valsartan Manufacturing Plant Setup Report 2025: Cost Analysis and Investment Opportunities here

News-ID: 4223203 • Views: …

More Releases from IMARC Group

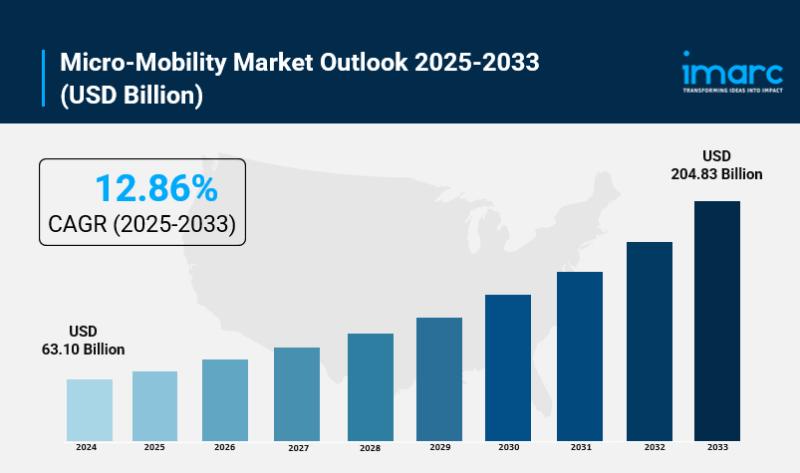

Micro-Mobility Market Size, Share, Industry Trends, Growth Factors and Forecast …

IMARC Group, a leading market research company, has recently released a report titled "Micro-Mobility Market Size, Share, Trends and Forecast by Type, Propulsion Type, Sharing Type, Speed, Age Group, Ownership, and Region, 2025-2033." The study provides a detailed analysis of the industry, including the global micro-mobility market share, size, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Micro-Mobility Market…

Bisphenol A Production Plant Setup Cost 2025: Future Outlook and Investment Oppo …

Bisphenol A (BPA) is an organic chemical compound primarily used in producing polycarbonate plastics and epoxy resins. It is a key ingredient in items like water bottles, food containers, and coatings for metal cans, offering durability and clarity. BPA has drawn attention due to potential health concerns, as it can mimic estrogen and disrupt endocrine functions if ingested in large amounts, leading to regulatory scrutiny in consumer products. Despite this,…

White Cement Manufacturing Plant Setup Report 2025: Cost, Raw Material Requireme …

IMARC's new report titled "White Cement Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a white cement manufacturing plant. The study covers all the requisite aspects that one needs to know while entering the white cement industry. It provides a comprehensive breakdown of the white cement manufacturing plant setup cost, offering detailed insights into…

How to Start a Date Processing Plant Setup in Saudi Arabia 2025: Details Project …

IMARC Group's report, "Date Processing Plant Setup in Saudi Arabia 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a processing plant. The date processing plant setup in Saudi Arabia report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Date Processing Plant Setup in Saudi Arabia Summary

• Comprehensive guide for setting up a…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…