Press release

Establishing a Profitable Fabric Softener Manufacturing Plant in 2025: Project Cost Details and Material Requirements

Fabric Softener Manufacturing Plant Report Overview:IMARC's new report titled "Fabric Softener Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for establishing a manufacturing plant. The study covers all the essential aspects that one needs to know while entering the fabric softener industry. It offers a comprehensive breakdown of the plant setup cost, providing detailed insights into capital investment, infrastructure planning, and resource allocation. This report is a must-read for entrepreneurs, investors, researchers, consultants, and business strategists who have any stake in the industry. Additionally, the report analyzes the fabric softener manufacturing plant cost, helping stakeholders assess financial feasibility and long-term profitability.

Download Your Sample Report Now: https://www.imarcgroup.com/fabric-softener-manufacturing-plant-project-report/requestsample

Introduction

Fabric softeners are chemical formulations designed to improve the texture, feel, and longevity of fabrics by reducing static, softening fibers, and imparting a pleasant fragrance. Commonly made using conditioning agents, emulsifiers, and fragrance compounds, they are essential in both household and industrial laundry applications. The products are available in liquid, sheet, and concentrated forms, catering to diverse consumer needs. With advancements in formulation science, modern fabric softeners are being developed to enhance performance while being eco-friendly, biodegradable, and suitable for various washing conditions. Their growing use in commercial laundries, textile processing, and household segments has made them a vital part of the detergent and cleaning products industry.

Market Drivers and Outlook:

The fabric softener market is driven by growing awareness of fabric care, hygiene, and comfort among consumers. Rising disposable incomes, increasing adoption of premium laundry products, and urbanization have further boosted demand. The expanding hospitality and textile sectors are also key contributors to market growth. Furthermore, the shift toward eco-friendly and hypoallergenic softeners has opened new innovation avenues for manufacturers. The integration of advanced formulations that enhance softness, fragrance retention, and sustainability continues to strengthen the product's market presence. As a result, the fabric softener industry is expected to witness steady expansion in the coming years, supported by evolving consumer preferences and environmental considerations.

Key Steps:

Manufacturing Process and Technical Workflow

This report offers detailed information related to the process flow and unit operations involved in a fabric softener manufacturing plant project. It also provides data on raw material requirements, mass balance, quality assurance criteria, and key technical tests necessary for production.

Aspects Covered

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Buy Full Report Now: https://www.imarcgroup.com/checkout?id=9768&method=1911

Infrastructure and Setup Requirements

This section presents a complete analysis of the key factors involved in establishing a fabric softener manufacturing plant. It covers aspects such as land selection, environmental impact, layout design, and cost structure. It also includes a breakdown of expenses related to machinery, utilities, raw materials, packaging, transportation, and workforce.

Key Components:

• Land, Location, and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Financial Projections and Economic Viability

This section provides an in-depth financial evaluation of the fabric softener plant setup, including capital expenditure (CapEx), operating costs (OpEx), revenue projections, and profitability analysis. It also includes payback period, NPV, and liquidity assessments to help investors make informed decisions.

Key Financial Elements

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Frequently Asked Questions:

• What are the raw material requirements for fabric softener manufacturing?

• How much does it cost to set up a fabric softener plant?

• Which machinery is required for fabric softener production?

• Is fabric softener manufacturing a profitable business in 2025?

Key Considerations for Plant Design and Operations:

• Production Capacity: Align plant design with desired production volume.

• Automation Levels: Choose between semi-automated or fully automated systems based on investment and labor considerations.

• Location Adaptation: Select strategic locations for easy raw material access and market reach.

• Product Flexibility: Equip the plant to produce multiple variants such as concentrated or eco-friendly softeners.

• Sustainability Features: Incorporate renewable energy and eco-friendly practices.

• Raw Material Sourcing: Build a reliable and cost-effective supply chain for consistent production.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=9768&flag=C

About Us:

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and develop impactful business strategies.

Our Expertise Includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and Factory Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Procurement and Supply Chain Research

• Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St, Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Establishing a Profitable Fabric Softener Manufacturing Plant in 2025: Project Cost Details and Material Requirements here

News-ID: 4254563 • Views: …

More Releases from IMARC Group

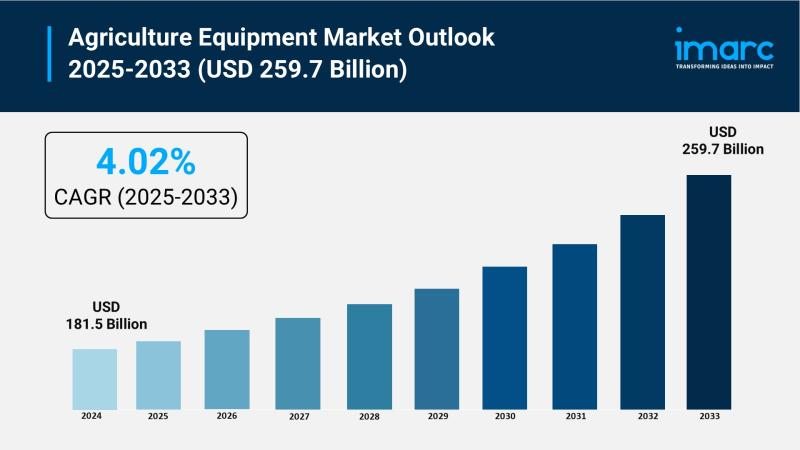

Agriculture Equipment Market Size Worth USD 259.7 Billion Globally by 2033 at a …

Market Overview:

The Agriculture Equipment Market is experiencing rapid growth, driven by Government Push for Farm Mechanization, Labor Shortage in Agriculture Sector and Rising Demand for Food Production. According to IMARC Group's latest research publication, "Agriculture Equipment Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global agriculture equipment market size was valued at USD 181.5 Billion in 2024. Looking forward, IMARC Group estimates the market to…

New Report Estimates Europe Digital Health Market Value of USD 292.95 Billion by …

Market Overview

The Europe digital health market was valued at USD 117.77 Billion in 2024 and is forecasted to reach USD 292.95 Billion by 2033, growing at a CAGR of 10.7% during the period 2025-2033. This growth is driven by advanced technologies improving patient care and efficiency, regulatory support for telehealth and data privacy, an aging population, and increasing emphasis on personalized medicine and cost reduction strategies.

Download a sample copy of…

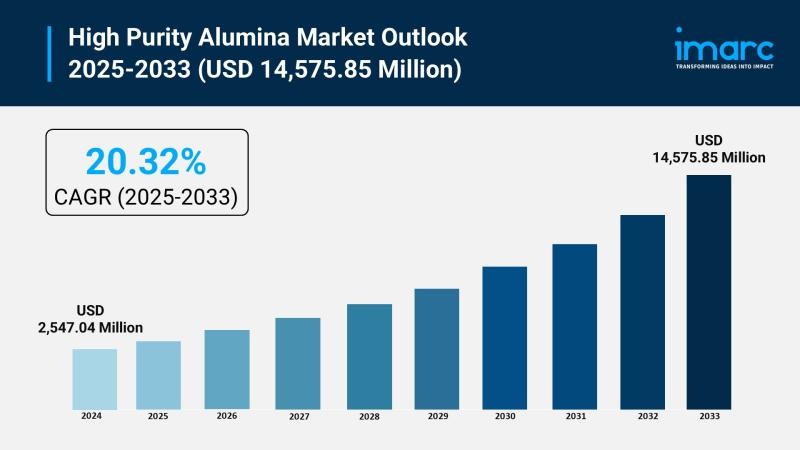

High Purity Alumina Market Size to Hit USD 14,575.85 Million by 2033 | With a 20 …

Market Overview:

The high purity alumina market is experiencing rapid growth, driven by expanding electric vehicle and battery production, the global shift to energy-efficient led lighting, and advancements in semiconductor and high-tech electronics. According to IMARC Group's latest research publication, "High Purity Alumina Market Size, Share, Trends and Forecast by Purity Level, Production Method, Application, and Region, 2025-2033", The global high purity alumina market size was valued at USD 2,547.04 Million…

How Are IoT and AI Advancements Driving the Global Smart Building Market?

Market Overview

The global smart building market is forecasted to grow at a CAGR of 9.58% during the period 2025-2033. Growth is propelled by advancements in Internet of Things (IoT) and artificial intelligence (AI), increasing emphasis on energy efficiency, integrated security systems, and supportive government regulations promoting occupant comfort. The market benefits from rapid urbanization and technological innovations across various sectors.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

Market Key…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…