Press release

Differences Between Flaskless Molding Machines and Flask Molding Machines

Flaskless molding machines [https://www.junengmachinery.com/servo-molding-machine-products/] and flask molding machines are two primary types of equipment used in foundry production for making sand molds (castings molds). Their core distinction lies in whether they use a flask to contain and support the molding sand. This fundamental difference leads to significant variations in their processes, efficiency, cost, and applications.Key Differences

Core Concept:

Flask Molding Machine: Requires the use of a flask during mold making. A flask is a rigid metal frame (usually upper and lower halves) used to hold molding sand, providing support and positioning during molding, handling, flipping, closing (assembly), and pouring.

Flaskless Molding Machine: Does not require traditional flasks during mold making. It utilizes special high-strength molding sand (typically self-hardening sand or highly compacted clay-bonded sand) and precise pattern design to create molds with sufficient inherent strength and rigidity. This allows the molds to be handled, closed, and poured without the need for external flask support.

Process Flow:

Flask Molding Machine:

Requires preparation and handling of flasks (cope and drag).

Typically involves making the drag mold first (filling and compacting sand in the drag flask placed on the pattern), flipping it, then making the cope mold on top of the flipped drag (placing the cope flask, filling, and compacting).

Requires pattern removal (separating the flask from the pattern).

Requires mold closing (accurately assembling the cope and drag flasks together, usually using flask alignment pins/bushes).

The closed mold (with flasks) is poured.

After pouring and cooling, shakeout is required (separating the casting, gating/risers, and sand from the flask).

Flasks need cleaning, maintenance, and reuse.

Flaskless Molding Machine [https://www.junengmachinery.com/servo-molding-machine-products/]:

No separate flasks are needed.

Simultaneously compacts the cope and drag molds directly onto a specially designed double-sided pattern plate (cavities for both halves on one plate) or precisely matched separate cope and drag patterns.

After compaction, the cope and drag molds are ejected vertically or horizontally and directly closed together with precise alignment (relying on the machine's accurate guides, not flask pins).

The closed mold (without flasks) is poured.

After pouring and cooling, the sand mold is broken apart during shakeout (often easier due to the absence of flasks).

Main Advantages:

Flask Molding Machine:

Wide Adaptability: Suitable for castings of almost all sizes, shapes, complexities, and batch sizes (especially large, heavy castings).

Lower Sand Strength Requirements: The flask provides primary support, so the required inherent strength of the molding sand is relatively lower.

Lower Initial Investment (Single Machine): Basic flask machines (e.g., jolt-squeeze) have a relatively simple structure.

Flaskless Molding Machine:

Very High Production Efficiency: Eliminates flask handling, flipping, and cleaning steps. Highly automated, with fast production cycles (can reach hundreds of molds per hour), especially suitable for mass production.

Significant Cost Savings: Saves costs on flask purchase, repair, storage, and handling; reduces floor space; lowers sand consumption (lower sand-to-metal ratio); reduces labor costs.

Higher Casting Dimensional Accuracy: Mold closing accuracy is ensured by high-precision equipment, reducing mismatch caused by flask distortion or pin/bush wear; less mold distortion.

Improved Working Conditions: Reduces labor intensity and minimizes dust and noise (high automation).

Simplified Sand System: Often uses more uniform, high-quality sand (e.g., unbonded sand for lost foam, high-pressure compacted clay sand), making sand preparation and recycling simpler.

Safer: Avoids risks associated with handling heavy flasks.

Main Disadvantages:

Flask Molding Machine:

Relatively Lower Efficiency: More process steps, longer auxiliary times (especially with large flasks).

Higher Operating Costs: High costs for flask investment, maintenance, storage, and handling; relatively higher sand consumption (higher sand-to-metal ratio); requires more floor space; needs more manpower.

Relatively Limited Casting Accuracy: Subject to flask accuracy, distortion, and pin/bush wear, with higher risk of mismatch.

Higher Labor Intensity, Relatively Poorer Environment: Involves heavy manual tasks like flask handling, flipping, cleaning, along with dust.

Flaskless Molding Machine:

High Initial Investment: The machines themselves and their automation systems are typically very expensive.

Very High Sand Requirements: Molding sand must have exceptionally high strength, good flowability, and collapsibility, often at a higher cost.

High Pattern Requirements: Double-sided pattern plates or high-precision matched patterns are complex and costly to design and manufacture.

Primarily Suitable for Mass Production: Pattern (plate) changes are relatively cumbersome; less economical for small batch production.

Casting Size Limitation: Typically better suited for small to medium-sized castings (though large flaskless lines exist, they are more complex and expensive).

Strict Process Control Required: Requires very precise control over sand properties, compaction parameters, etc.

Typical Applications:

Flask Molding Machine: Widely used for producing castings in single pieces, small batches, multiple varieties, large sizes, and heavy weights. Examples include machine tool beds, large valves, construction machinery components, marine castings. Common equipment: Jolt-squeeze machines, jolt-ram machines, flask-type shoot-squeeze machines, flask-type matchplate lines, flask-type high-pressure molding lines.

Flaskless Molding Machine: Primarily used for mass production of small to medium-sized, relatively simple-shaped castings. It's the mainstream choice in automotive, internal combustion engine, hydraulic component, pipe fitting, and hardware industries. Typical representatives:

Vertically Parted Flaskless Shoot-Squeeze Machines: E.g., DISAMATIC lines (DISA), the most widely used flaskless system, highly efficient for small/medium castings.

Horizontally Parted Flaskless Molding Machines: While strictly "flaskless" after stripping, they sometimes use a molding frame (similar to a simple flask) during compaction. Also very efficient, commonly used for engine blocks and cylinder heads.

Summary Comparison Table

Feature

Flask Molding Machine

Flaskless Molding Machine

Core Feature

Uses Flasks

No Flasks Used

Mold Support

Relies on Flask

Relies on Sand Strength & Precise Closing

Process Flow

Complex (Move/Fill/Flip/Close/Shakeout flasks)

Simplified (Direct Mold/Close/Pour)

Production Speed

Relatively Lower

Very High (Suits Mass Production)

Per-Piece Cost

Higher (Flasks, Sand, Labor, Space)

Lower (Clear Advantage in Mass Production)

Initial Investment

Relatively Lower (Basic) / High (Auto Line)

Very High (Machine & Automation)

Casting Accuracy

Moderate

Higher (Machine Ensured Closing Accuracy)

Sand Requirements

Relatively Lower

Very High (Strength, Flowability, Collapsibility)

Pattern Requirements

Standard Single-Sided Patterns

High-Precision Double-Sided/Matched Plates

Suitable Batch Size

Single Piece, Small Batch, Large Batch

Primarily Mass Production

Suitable Casting Size

Virtually Unlimited (Excels in Large/Heavy)

Primarily Small-Medium Castings

Labor Intensity

Higher

Low (High Automation)

Working Environment

Relatively Poor (Dust, Noise, Heavy Lifting)

Relatively Better

Typical Applications

Machine Tools, Valves, Heavy Machinery, Marine

Auto Parts, Engine Comps, Pipe Fittings, Hardware

Representative Equipment

Jolt-Squeeze, Flask Matchplate, Flask HPL

DISAMATIC (Vert. Parting) etc.

Simply Put:

Needs a flask to support the sand mold right Flask Molding Machine right Flexible & versatile, suitable for various situations, but slower & higher cost.

Sand mold is strong & rigid by itself, no flask needed right Flaskless Molding Machine right Extremely fast & lower cost, ideal for mass-produced small parts, but high investment & higher barriers to entry.

The choice between them depends on the specific casting requirements (size, complexity, batch size), investment budget, production efficiency goals, and cost targets. In modern foundries, mass production typically favors efficient flaskless lines, while multi-variety/small-batch or large castings rely more on flask molding.

Image: https://www.junengmachinery.com/uploads/junengFactory.jpg [https://www.junengmachinery.com/about-us/company-profile/]

Quanzhou Juneng Machinery Co.,Ltd. is a subsidiary of Shengda Machinery Co.,Ltd. specializing in casting equipment. A high-tech R&D enterprise that has long been engaged in the development and production of casting equipment, automatic molding machines, and casting assembly lines.

If you need a Flaskless molding machine [https://www.junengmachinery.com/servo-molding-machine-products/], you can contact us through the following contact information:

Sales Manager : zoe

E-mail : zoe@junengmachine.com [mailto:zoe@junengmachine.com]

Telephone : +86 13030998585

Media Contact

Company Name: Quanzhou Juneng Machinery Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=differences-between-flaskless-molding-machines-and-flask-molding-machines]

Country: China

Website: https://www.junengmachinery.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Differences Between Flaskless Molding Machines and Flask Molding Machines here

News-ID: 4261466 • Views: …

More Releases from ABNewswire

Polish Client Explores Risheng Factory: Forging Stronger Ties in Power Equipment …

Warm Reception & Strategic Dialogue

The visit commenced in our sleek, well-appointed conference room, where the Polish clients was warmly received. Around a table adorned with traditional tea and local snacks, both parties engaged in a strategic dialogue. Here, we mapped out collaboration frameworks, shared insights into industry trends, and aligned on mutual goals for innovation in power equipment.

Image: https://ecdn6-nc.globalso.com/upload/p/3832/image_other/2025-11/wechat-image_20251106151858.jpg

Behind-the-Scenes of Precision Manufacturing

The clients then ventured into our production workshops, where…

GrandStar Shines at ITMA Singapore 2025 with Its Next-Generation Tricot Warp Kni …

Image: https://www.grandstarcn.com/uploads/web1.jpg

During ITMA Singapore 2025 (October 28-31), GrandStar Warp Knitting Company made a powerful impression by unveiling its latest Tricot warp knitting machine [https://www.grandstarcn.com/curtain-machine-karl-mayer-warp-knitting-machine-raschel-machine-for-lace-curtain-fabric.html], which quickly became one of the most talked-about highlights of the exhibition's opening day. The booth attracted a continuous flow of industry professionals eager to witness GrandStar's innovations in warp knitting technology - machines built upon the values of efficiency, stability, and cost optimization.

GrandStar COP4E+M: The…

2025 Vending Forecast: Chuanbo's Multi-Language, AI-Powered Cotton Candy Machine …

As the global vending machine industry hurtles toward a $275.5 billion valuation in 2025, entertainment retail is emerging as the breakout star, projected to surge by 30% year-over-year. This explosive growth isn't just about snacks-it's fueled by immersive, AI-driven experiences that turn impulse buys into memorable moments, especially in the booming parent-child and women's consumer segments. Leading the charge is Guangzhou Chuanbo Information Technology Co., Ltd [https://www.robotscandy.com/]. (Chuanbo Technology), whose…

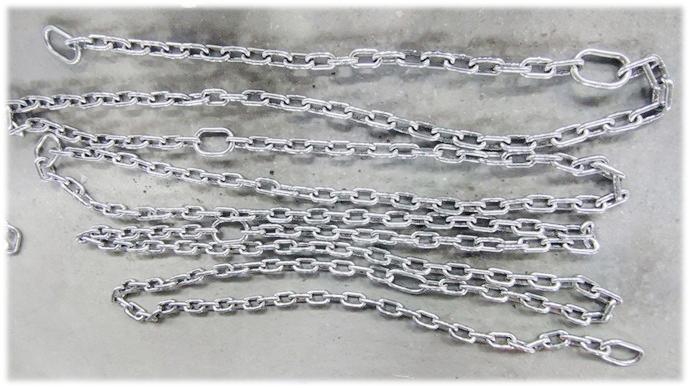

SCIC Stainless Steel Pump Lifting Chains: Engineered for Reliability in the Worl …

The safe and efficient retrieval of submersible pumps is a critical, yet challenging, operation for industries (water treatment in particular) worldwide. Corrosion, confined spaces, and extreme depths create a complex set of demands for lifting equipment. SCIC specializes in engineering solutions for these exact challenges. Our stainless steel pump lifting chains are not just components; they are integrated safety systems designed to ensure that maintenance and repair operations in water…

More Releases for Flask

Metal Thermos Flask Market Outlook and Future Projections for 2030

The metal thermos flask market represents a dynamic and continually evolving landscape, shaped by changing consumer demands and technological advancements. In this comprehensive report, we provide an in-depth exploration of the market, designed for a wide range of stakeholders including manufacturers, suppliers, distributors, and investors. Our goal is to equip industry participants with essential insights that enable informed decision-making in an ever-changing market environment. This analysis not only examines the…

Conical Flask Market Size 2024 to 2031.

Market Overview and Report Coverage

A conical flask, also known as an Erlenmeyer flask, is a laboratory glassware used for mixing, storing, and heating liquids. It has a conical shape with a narrow neck and a flat bottom, making it ideal for swirling liquids.

The current outlook for the Conical Flask Market is positive, with an expected growth at a CAGR of 5.60% during the forecasted period. This growth can…

Bioreactor Flask Market Size, Players, Revenue Analysis 2023-2030

Bioreactor Flask Market Overview 2023:

The Bioreactor Flask Market 2023 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the Bioreactor Flask market. This report explores all the key factors affecting the growth of the Bioreactor Flask…

Global Multi-necked Flask Market - Opportunities & Forecasts, 2020-2029

Dhirtek Business Research and Consulting recently released its most comprehensive research report to date on the global multi-necked flask market. Through extensive research, analysts have provided an extensive look into the market's drivers and restraints, and identified the key milestones and trends that will shape its future.

Primary and secondary research methods were used to create this in-depth report. Through the analysis of the research, Dhirtek was able to identify the…

Filtering Flask Market- Projections & Estimations, Forecast by 2020-2029

The report includes vital information on the current size and projected growth of the entire market for filtering flask and its relevant sectors. It also includes market characteristics, top suppliers, consumer preference patterns, and geographic market potential. Dhirtek Business Research and Consulting created this study using both primary and secondary sources. Primary sources included core and associated industry specialists, as well as those associated with service providers, deployment engineers, maintenance…

Flat Bottom Flask Market - Global Trends & Forecasts to 2020-2029

Dhirtek Business Research and Consulting has added a new research report to its vast library. The study report, titled flat bottom flask, analyses market trends and dynamics objectively. Analysts compared historical market data to current market patterns to provide a clear picture of the market's direction. The study includes SWOT analysis and Porter's five forces analysis to provide readers with an in-depth overview of the key variables that are expected…