Press release

Calcined Anthracite Industry Forecast Data: Metallurgy Application at 48.1% Revenue in 2025 | Fact.MR

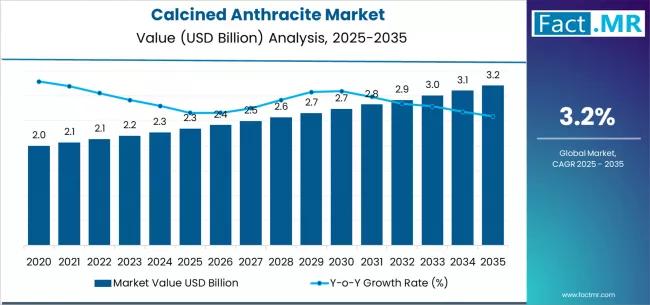

The global calcined anthracite market is projected to expand from USD 2,340.8 million in 2025 to approximately USD 3,207.5 million by 2035, reflecting a compound annual growth rate (CAGR) of about 3.2% over the forecast period. Growth is underpinned by increasing demand for high-quality carbon additives in metallurgy, rising adoption of advanced processing technologies, and expanding industrial applications in aluminum, steel, and foundry sectors.Calcined anthracite-which is anthracite coal subjected to high-temperature calcination to enhance carbon content and performance-is critical in metallurgical processes such as cathode and carbon additives, foundry recarburizers, and water filtration applications. As manufacturers push for higher efficiency, lower emissions, and improved material properties, the role of premium calcined anthracite is rising.

➤Key Market Insights at a Glance

Market Value (2025): USD 2,340.8 million

Forecast Value (2035): USD 3,207.5 million

CAGR (2025-2035): ~3.2%

Leading Grade Type: Electrically Calcined Anthracite (ECA) (~57.4% share)

Dominant Application: Cathode / Carbon Additive (Metallurgy) (~48.1% share)

Key Growth Regions: Asia-Pacific, Europe, North America

Top Players: RHEINFELDEN Carbon; Asbury Carbons; Ningxia TLH Group; Elkem Carbon; Jincheng Anthracite; Dev Energy; Kingstone Carbon Group

To Access the Complete Data Tables & in-depth Insights, Request a Discount on this report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9357

➤Market Drivers / Growth Overview

Several interlinked factors are driving the calcined anthracite market:

Metallurgical demand growth: Expansion of aluminum production and steel / foundry operations requires high-carbon additives for cathodes, recarburizers and purification processes, supporting calcined anthracite uptake.

Purity & performance advantages: Calcined anthracite offers high carbon content, low ash and stable structure-attributes critical for advanced metallurgical processes, enhancing material performance and efficiency.

Industrial modernization & regulation: Governments and manufacturers emphasise efficiency, emission-reduction and advanced materials; calcined anthracite meets performance-standards and supports cleaner manufacturing.

Global expansion of high-carbon material applications: Beyond steel and aluminum, applications such as water filtration, batteries and speciality carbon additives are emerging, broadening the addressable market.

Regional growth in high-intensity manufacturing zones: Industrial expansion in Asia-Pacific, Eastern Europe and Latin America is increasing local demand for advanced carbon materials, driving market growth.

At the same time, growth is tempered by constraints including high processing cost, raw-material sourcing challenges and the technical complexity of advanced calcination systems.

➤Segmentation & Key Drivers

By Grade:

Electrically Calcined Anthracite (ECA) leads the market, capturing ~57.4% share due to its high quality and suitability for demanding applications.

Gas Calcined Anthracite (GCA) holds the remainder, preferred in cost-conscious or less-stringent applications.

By Application:

Cathode / Carbon Additive (Metallurgy) is the largest application segment (~48.1% share) due to intensive use in aluminum and steel production.

Recarburizer / Foundry follows (~33.7%) addressing steel, cast-iron and metal-casting processes.

Water Filtration & Others (~18.2%) cover emerging roles in filtration, environmental and specialty carbon markets.

By End-Use Industry:

Aluminum & Metals are major adopters owing to strict quality and carbon-additive requirements.

Steel & Foundry represent significant demand given structural applications and carbon-intensive processes.

Others include filtration, battery materials and other niche high-carbon contexts.

Key segmentation drivers include feedstock quality, process specification, regional manufacturing maturity and technical service support.

➤Regional & Country Insights

Asia-Pacific: Dominant region-led by China and India-due to strong metallurgical growth, local carbon-materials manufacturing and industrial expansion.

Europe: Mature market with steady demand, strong quality requirements and ongoing modernization of steel and foundry infrastructure.

North America: Growth in advanced manufacturing zones, aluminum recycling and high-carbon additive upgrades supports demand.

Latin America / Middle East & Africa: Emerging regions, where industrialisation and metallurgical capacity expansion create incremental opportunities.

Regional performance is shaped by industrial activity levels, carbon-materials supply chains, regulatory environments and manufacturing investment cycles.

➤Competitive Landscape

The calcined anthracite market is moderately competitive, with leading players maintaining strong positions through quality, process expertise and distribution networks. Prominent companies include RHEINFELDEN Carbon, Asbury Carbons, Ningxia TLH Group, Elkem Carbon, and Jincheng Anthracite.

Competitive strategies focus on:

Advancing calcination technology and process optimisation to reduce cost and improve product performance.

Expanding manufacturing capacity and geographic presence to serve regional demand and improve lead-times.

Offering application-specific product portfolios (e.g., battery grade, filtration grade, metallurgy grade) to address diverse end-use requirements.

Partnering with metallurgy customers and research organisations to develop tailored carbon-material solutions and service support.

➤Market Outlook & Strategic Insights

Over the forecast period through 2035, the calcined anthracite market is expected to deliver steady, modest growth. Strategic insights for stakeholders include:

Prioritising high-purity and specialty grades (especially ECA) to meet stringent metallurgy and advanced material applications.

Targeting emerging manufacturing hubs (particularly in Asia-Pacific) where growth potential is highest and local production capacity is expanding.

Investing in enhanced calcination technology and process efficiency to manage cost pressures and ensure competitive advantage.

Diversifying into emerging end-uses (e.g., water-filtration carbon media, battery additive) to broaden revenue streams beyond traditional metallurgy.

Strengthening customer service, technical support and application-engineering capabilities to build long-term relationships in complex industrial supply chains.

Companies that align these strategies-while maintaining product quality, supply reliability and operational efficiency-will be well positioned to capture value in a market projected to reach over USD 3.2 billion by 2035.

Browse Full Report: https://www.factmr.com/report/calcined-anthracite-market

➤Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report: https://www.factmr.com/checkout/9357

Have specific requirements or need assistance on report pricing or have a limited budget? Please contact sales@factmr.com

➤Related Reports:

Calcined Alumina Market: https://www.factmr.com/report/2410/calcined-alumina-market

Calcined Kaolin Market: https://www.factmr.com/report/3152/calcined-kaolin-market

Sodium Silicate Market: https://www.factmr.com/report/sodium-silicate-market

Structural Insulated Panels Market: https://www.factmr.com/report/structural-insulated-panels-market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

➤About Fact.MR:

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Calcined Anthracite Industry Forecast Data: Metallurgy Application at 48.1% Revenue in 2025 | Fact.MR here

News-ID: 4262139 • Views: …

More Releases from Fact.MR

USA Demand for Microbiome Skincare Products in USA Outlook 2025-2035: Key Develo …

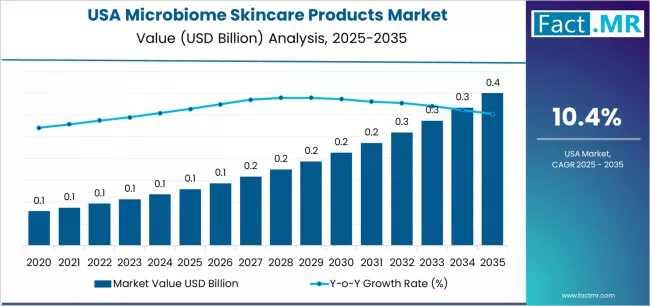

The U.S. microbiome skincare market is projected to experience rapid, data-driven growth over the next decade, driven by rising consumer awareness, ingredient innovation, and the integration of personalized diagnostics. Analysts estimate the U.S. microbiome skincare segment at approximately USD 0.13 billion in 2025, with a projected increase to USD 0.35 billion by 2035, representing a compound annual growth rate (CAGR) of 10.4%.

To access the complete data tables and in-depth insights,…

USA Demand for Lubricants in USA Outlook 2025-2035: Key Developments and Future …

The U.S. lubricants market is projected to experience steady growth through 2035, driven by shifts in mobility, industrial demand, and sustainability trends. The market was valued at approximately $41.2 billion in 2024 and is expected to grow at a compound annual growth rate (CAGR) of 2.5%, reaching $52 billion by 2035.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12463

…

European Demand for Intermodal Freight Transportation in UK Outlook 2025-2035: K …

"Demand for intermodal freight transport connecting the UK and continental Europe is projected to grow at a CAGR of 6.8% between 2025 and 2035, driven by rising trade volumes, decarbonization mandates, and digital logistics innovations. The intermodal market, encompassing rail, short-sea shipping, and last-mile road delivery, is expected to handle over 18 million TEUs (twenty-foot equivalent units) annually by 2035, up from 10.2 million TEUs in 2025.

To access the complete…

USA Demand for Hydroxyapatite in USA Outlook 2025-2035: Key Developments and Fut …

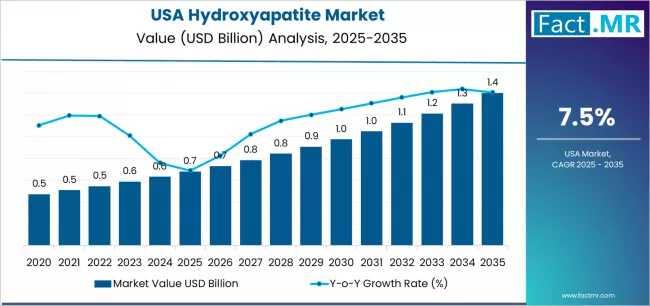

The United States hydroxyapatite (HAp) market is projected to experience sustained, data-driven growth from 2025 through 2035, fueled by rising clinical demand, technological innovation, and expanded applications in regenerative medicine. Market modeling indicates that U.S. consumption of hydroxyapatite will nearly double over the next decade, with strong adoption in orthopedic, dental, and advanced biomaterial sectors.

To access the complete data tables and in-depth insights, request a Discount On The Report here:…

More Releases for Calcined

Calcined Anthracite Market Size, Share, Growth 2031

Global Calcined Anthracite Market Size was estimated at USD 517 million in 2021 and is projected to reach USD 722.6 million by 2028, exhibiting a CAGR of 4.9% during the forecast period.

The Calcined Anthracite Market 2024 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It…

Calcined Anthracite Market Opportunity | Size | Research Report

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global Calcined Anthracite Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

The calcined anthracite market is poised for substantial growth, driven by its diverse applications in industries such as steel manufacturing, power generation, and the production…

Calcined Petcoke Market Will Hit Big Revenues In Future | Oxbow, Calcined petrol …

Advance Market Analytics published a new research publication on “Global Calcined Petcoke Market Insights, to 2026” with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Calcined Petcoke market was mainly driven by the increasing R&D spending across the world.

Some of the key players profiled…

Calcined Petcoke Market Outlook 2018 to 2028

Global Calcined Petcoke Market: Overview

The global calcined petcoke market has flourished noticeably from the changing demand dynamic in end-use industries. Sizeable revenues for the market come from the profuse demand from the aluminum industry, where the high purity carbon material is used in the fabrication as well as utilization of smelter anodes. Substantial demand for calcined petcoke also comes from the steel industry, where it is notably used as a…

Calcined Alumina Market Highlights by 2026

Calcined Alumina Market: Introduction

Calcined Alumina also known as aluminum oxide is produced by continuous calcination of alumina at various temperatures. The properties of the final product can be controlled by the controlling the calcination temperatures. Calcined Alumina doesn’t undergo a loss in weight on firing and is harder compared to tungsten carbide or zircon. Calcined alumina can sustain high temperatures and has explicit properties including high mechanical strength & hardness,…

Calcined Petroleum Coke Market Research Report 2018

This report studies the global Calcined Petroleum Coke market status and forecast, categorizes the global Calcined Petroleum Coke market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India, Southeast Asia).

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-calcined-petroleum-coke-2018-320

The major manufacturers covered in this report

Oxbow

Aminco Resource

Aluminium Bahrain

Asbury Carbons

Atha Group

Carbograf

RAIN CII CARBON

Minmat Ferro Alloys

Ferrolux

Shandong KeYu…