Press release

Setting Up a Keyboard and Mouse Manufacturing Unit: Market Insights, Capex, and Profit Analysis

A keyboard and mouse constitute the primary human-computer interface, enabling efficient text input, navigation, and command execution. These devices combine mechanical or membrane-based switches, optical or laser sensors, and ergonomic design elements to support accuracy, comfort, and long-term usability across consumer, gaming, and professional environments.Setting up a keyboard and mouse manufacturing plant requires investment in plastic molding, PCB assembly, switch integration, sensor calibration, and quality-control systems. Efficient supply-chain sourcing, standardized production workflows, and compliance with international safety certifications support scalable operations and competitive market entry.

IMARC Group's "Keyboard and Mouse Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as keyboard and mouse manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/keyboard-mouse-manufacturing-plant-project-report/requestsample

Keyboard and Mouse Industry Outlook 2025:

The keyboard and mouse industry outlook for 2025 indicates steady expansion supported by continued growth in gaming peripherals, rising adoption of wireless and Bluetooth-enabled devices, and increasing demand from remote work and education environments. Advancements in mechanical switch technology, ergonomic design, and energy-efficient sensors enhance product value and market competitiveness. Strong replacement cycles, broader penetration in emerging economies, and the integration of customizable features such as RGB lighting contribute to sustained market momentum.

Key Insights for Keyboard and Mouse Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Keyboard and Mouse Plant:

• Land and Building Costs: Expenses for purchasing or leasing space, construction, and basic facility setup.

• Machinery and Equipment: Investment in molding machines, PCB assembly lines, testing systems, and packaging units.

• Raw Materials Procurement: Costs for plastics, switches, PCBs, sensors, wiring, and electronic components.

• Labor and Staffing: Wages for skilled technicians, assembly workers, quality controllers, and administrative staff.

• Utilities and Maintenance: Electricity, water, HVAC, and routine maintenance for machinery and facilities.

• Tooling and Molds: Expenditure on custom molds required for keycaps, casings, and mouse shells.

• Quality Control and Testing: Costs for reliability tests, calibration equipment, and compliance certification.

• Packaging and Logistics: Materials for packing finished products and expenses for storage and distribution.

• R&D and Prototyping: Investment in product design, prototyping, and performance optimization.

• Regulatory Compliance: Fees for safety certifications, environmental clearances, and industry standards adherence.

Economic Trends Influencing Keyboard and Mouse Plant Setup Costs 2025:

• Rising Component Prices: Increased costs for semiconductors, sensors, and switches due to persistent supply chain constraints.

• Higher Labor Expenses: Wage growth in major manufacturing hubs raising overall staffing and operational costs.

• Fluctuating Energy Prices: Variable electricity and fuel rates affecting production, molding, and assembly operations.

• Currency Exchange Volatility: Shifts in exchange rates influencing import prices for electronic components and machinery.

• Logistics and Freight Inflation: Elevated shipping and transport costs impacting inbound materials and outbound distribution.

• Technological Upgrades: Continuous need for automation and advanced testing systems increasing capital expenditure.

• Regulatory Compliance Costs: Stricter safety, environmental, and certification requirements adding to setup budgets.

• Global Demand Shifts: Growing demand for wireless and gaming peripherals shaping procurement strategies and investment needs.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9289&flag=C

Customization Options Available:

• Plant Location: Selection of a strategically suitable site for efficient operations and logistics.

• Plant Capacity: Determination of production output aligned with targeted manufacturing volumes.

• Machinery: Evaluation of automatic, semi-automatic, or manual equipment based on budget and efficiency needs.

• List of Machinery Providers: Evaluation of automatic, semi-automatic, or manual equipment based on budget and efficiency needs.

Challenges and Considerations for Investors in Keyboard and Mouse Plant Projects:

• High Initial Capital Investment: Significant funding required for machinery, molds, and advanced testing systems.

• Supply Chain Vulnerabilities: Dependence on sensors, switches, and PCB components exposed to global shortages.

• Intense Market Competition: Strong presence of established brands creating barriers to market entry and pricing power.

• Technology Obsolescence: Rapid innovation in wireless connectivity, sensors, and switch mechanisms increasing upgrade needs.

• Quality Control Demands: Strict performance and durability standards requiring robust testing and certification processes.

• Regulatory Compliance: Mandatory adherence to environmental, safety, and electromagnetic standards across markets.

• Skilled Workforce Requirements: Need for trained technicians and engineers to manage assembly and automation systems.

• Cost Management Pressures: Balancing production efficiency with rising input, labor, and energy costs.

Conclusion:

The keyboard and mouse manufacturing sector in 2025 presents steady growth opportunities supported by rising demand for wireless, ergonomic, and gaming-oriented peripherals. Establishing a production facility requires careful consideration of capital investment, supply chain dynamics, regulatory compliance, and technological advancements. Effective cost management, strategic sourcing, and adoption of modern manufacturing practices enhance competitiveness and long-term viability. This environment favors investors and manufacturers capable of balancing innovation with operational efficiency to meet evolving consumer and enterprise requirements.

Buy Now: https://www.imarcgroup.com/checkout?id=9289&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Setting Up a Keyboard and Mouse Manufacturing Unit: Market Insights, Capex, and Profit Analysis here

News-ID: 4277951 • Views: …

More Releases from IMARC Group

Planning an Industrial Adhesive Plant? Explore Full Cost & Investment Analysis 2 …

Introduction

Industrial adhesive refers to a broad category of high-performance bonding agents used to join, seal, and protect materials in manufacturing and engineering applications. Unlike traditional fasteners such as screws or nails, industrial adhesives create strong, lightweight, and uniform bonds that enhance structural integrity and product aesthetics. These adhesives come in various formulations-including epoxies, acrylics, polyurethane, hot melt, and silicone-each designed to deliver specific properties like heat resistance, flexibility, electrical insulation,…

Tulsi Oil (Holy Basil) Processing Plant Setup: Capital Investments, Operating Co …

IMARC's new report titled "Tulsi Oil (Holy Basil) Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a tulsi oil processing plant. The study covers all the key aspects you need to understand before entering the tulsi oil industry. It breaks down the plant setup costs in detail, giving you clear insights into what you'll…

Mosquito Repellent Patch Manufacturing Plant Setup Cost: Detailed Financial Plan …

IMARC's new report titled "Mosquito Repellent Patch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for establishing a mosquito repellent patch manufacturing unit. The study covers all major aspects required before entering the mosquito repellent patch industry. It explains plant setup costs in detail, offering clear insights into initial capital investment and infrastructure planning. This report is…

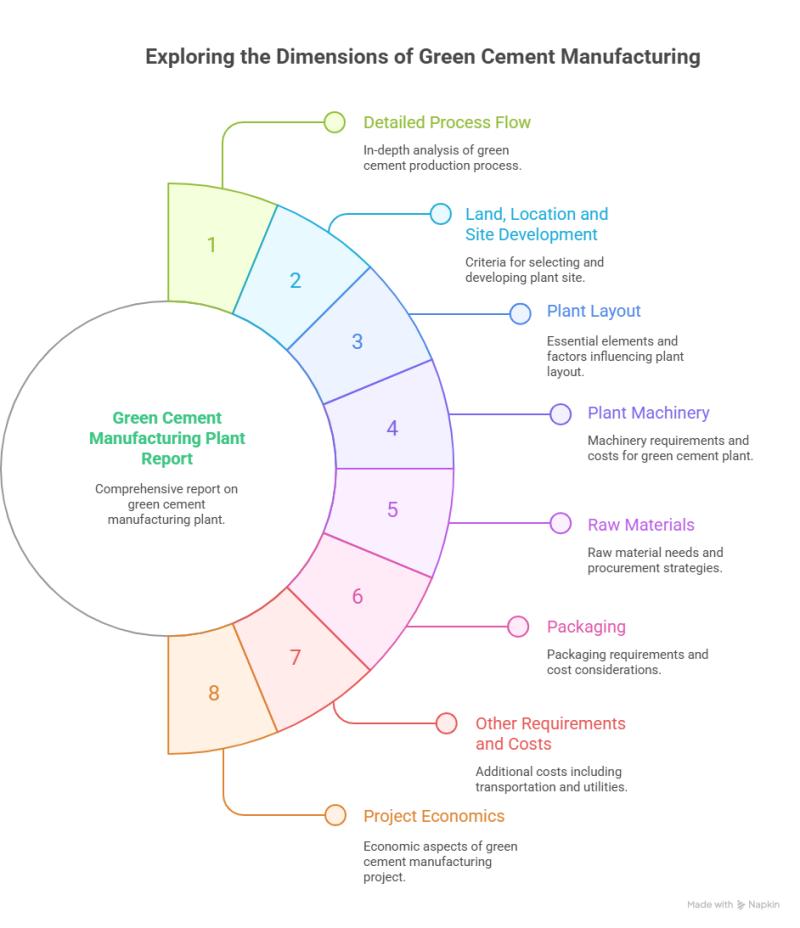

Green Cement Plant Setup 2025: Turnkey Cost, Process & Revenue Forecast

Green cement refers to a category of construction materials designed to reduce the environmental impact of traditional cement production through lower carbon emissions, alternative raw materials, and energy-efficient processing. It commonly incorporates industrial by-products such as fly ash, slag, or calcined clays, helping decrease clinker content and improve overall sustainability while maintaining comparable performance

Setting up a green cement manufacturing plant involves defining raw material sourcing strategies, selecting low-carbon production technologies,…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…