Press release

Advancing Industrial Automation with Next Generation ToF 3D Vision | Cube-eye

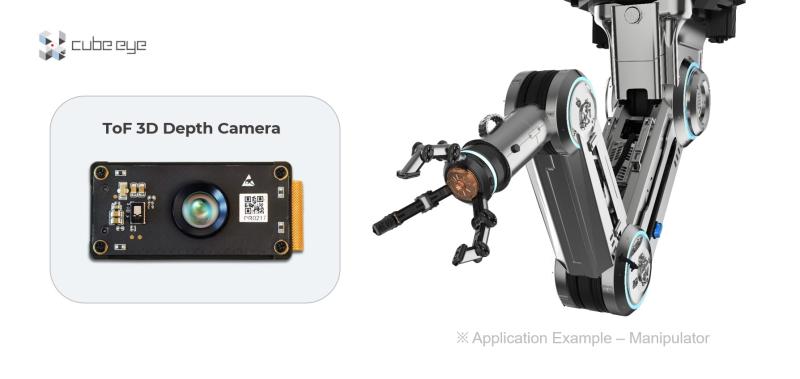

Cube-eye is shaping the future of industrial automation through advanced Time of Flight 3D camera technology that delivers fast depth sensing and high precision vision data. With a compact structure, built-in processing, and accurate depth output, this technology supports modern demands in inspection, alignment, volume measurement, bin picking, and robotic control. As smart factories continue to expand, Cube-eye provides dependable 3D recognition that enhances productivity, supports stable workflow movement, and maintains consistent quality across automated lines.In today's industrial landscape, visual intelligence has become a central element of automation systems. Depth data enables an accurate understanding of object shape, position, and orientation for tasks such as sorting, picking, transferring, and collision avoidance. A 3D ToF camera calculates coordinates and pose information, allowing robotic manipulators to identify precise gripping points and handle objects with confidence. As manufacturing speed increases and error tolerance decreases, demand for fast and repeatable 3D vision continues to grow.

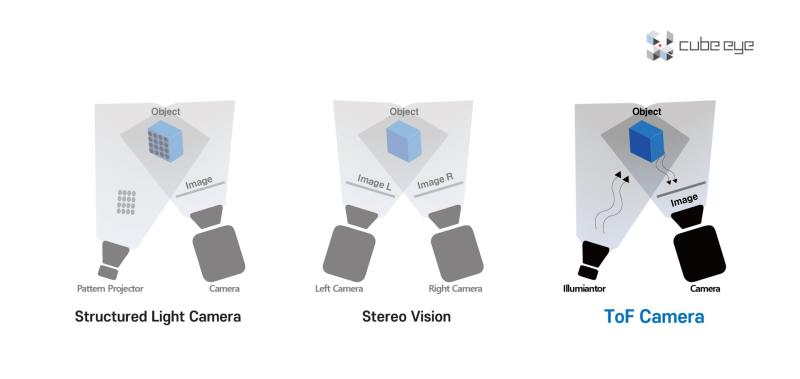

Traditional methods such as structured light and stereo vision have been widely used, yet both approaches show clear limitations in high-speed and motion-based environments.

Structured light cameras project patterns onto a surface to interpret depth and deliver strong accuracy, especially on small or reflective objects. However, slow frame rates and strict motion restrictions limit their usability on conveyor belts or continuous robot operations.

Stereo vision cameras use dual images to calculate depth in real time and offer installation flexibility, yet depth results are inconsistent, and processing loads remain heavy, often affecting overall system performance.

Time of Flight technology has emerged to overcome these drawbacks. A Cube-eye ToF camera measures the return time of emitted infrared light to generate instant distance data at high frame rates. This enables stable 3D acquisition during motion, making it suitable for robotic arms, mobile platforms, and logistics systems handling fast-moving targets. With simplified depth computation, built-in filtering, and support for USB, MIPI, and PoE, Cube-eye delivers reliable results with reduced processing burden and easy industrial integration. As factories continue moving toward fully automated environments, their Time of Flight cameras are becoming essential in achieving faster, smarter, and more efficient industrial vision.

Click here if you are interested in Cube-eye Cameras.

View More: Advancing Industrial Automation with Next Generation ToF 3D Vision

From December 3rd to 6th, 2025, iREX 2025 exhibition for robot will be held in Japan.

meerecompany will be attending this exhibition during this period.

If you have even the slightest interest in robot technology, visit meerecompany's booth at the iREX 2025 exhibition to experience cutting-edge robot technology!

- Exhibition Name: iREX 2025

- Exhibition Dates: December 3rd to 6th, 2025

- Exhibition Site: https://irex.nikkan.co.jp/

- Exhibition Address: (Tokyo Big Sight) 3 Chome-11-1 Ariake, Koto City, Tokyo

- meerecompany Booth: E7-02

South Korea

Cube-eye is shaping the future of industrial automation through advanced Time of Flight 3D camera technology that delivers fast depth sensing and high precision vision data.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Advancing Industrial Automation with Next Generation ToF 3D Vision | Cube-eye here

News-ID: 4290784 • Views: …

More Releases from Cube-eye

Transforming Industrial Automation with S100D ToF Cameras | Cube-eye

In today's industrial automation, accurate visual data is essential for efficient operations, and Cube-eye 3D depth cameras are leading this transformation. From quality inspection and part alignment to bin picking and logistics, Cube-eye cameras provide machines with the ability to detect objects' shape, position, and orientation. Robots handling small or irregular items need this precise 3D information, as even minor errors can impact productivity and quality.

Conventional technologies have limitations in…

The Rise of ToF Vision Systems for Smarter Factories and Robotics | Cube-eye

In modern industrial automation, fast and accurate visual data is essential for tasks such as inspection, alignment, and robotic guidance. Traditional 3D sensing methods like structured light and stereo vision struggle with speed, motion, and processing limitations. As factories adopt advanced robotics and AI, Cube-eye Time-of-Flight (ToF) industrial 3D cameras are emerging as the preferred solution, delivering reliable, real-time depth information to support smarter and more efficient automation.

Drawbacks of Structured…

The Power of Time of Flight Technology in Industrial Vision | Cube-eye

Cube-eye specializes in advanced Time of Flight 3D depth cameras built for industrial automation, robotics, logistics, and smart factory systems. The company focuses on delivering compact, intelligent, and high-speed 3D vision solutions that enable machines to recognize depth, detect object shapes, and identify positions with reliable accuracy. By combining hardware miniaturization with powerful depth-processing technology, Cube-eye aims to strengthen industrial automation with stable, real-time visual intelligence.

The Need for Better 3D…

Transforming Industrial Automation with S100D ToF Cameras | Cube-eye

In today's industrial automation, accurate visual data is essential for efficient operations, and Cube-eye 3D depth cameras are leading this transformation. From quality inspection and part alignment to bin picking and logistics, Cube-eye cameras provide machines with the ability to detect objects' shape, position, and orientation. Robots handling small or irregular items need this precise 3D information, as even minor errors can impact productivity and quality.

Conventional technologies have limitations in…

More Releases for ToF

ToF 3D Depth Camera S110D | Cube-eye

The Cube-eye ToF 3D Depth Camera S110D is a high-performance camera that uses Time-of-Flight (ToF) technology to determine the distance between objects in its field of view. This allows the camera to create precise and detailed 3D depth maps of its surroundings.

The S110D features a 100-degree field of vision with a resolution of 640x480 pixels. It can handle frame rates of up to 30 frames per second, making it ideal…

Cube-eye 3D Depth TOF Camera

Cube-eye is a 3D depth camera manufactured by Meerecompany, a South Korean company. It uses time-of-flight (ToF) technology to capture depth data.

Here's how ToF cameras work:

The camera emits a light source, typically a laser.

The light bounces off objects in the scene and returns to the camera.

The camera measures the time it takes for the light to make the round trip.

Based on the time it takes for the light to travel,…

ToF 3D Depth Camera I200 | CUBE EYE

The CUBE EYE ToF 3D Depth Camera I200 is a versatile and powerful solution for a variety of applications that require precise 3D depth data, particularly in outdoor settings. Its compact size, sunlight resistance, and long-range detection make it a viable challenger in robotics, augmented reality, security, and many other sectors.

Features of the Cube Eye ToF 3D Depth Camera I200

Sunlight Robustness: This is a major selling point of the I200.…

High-Performance ToF Camera | CUBE EYE

The CUBE EYE brand of time-of-flight (ToF) cameras was developed by meerecompany, an innovative high-resolution TOF 3D depth camera and 3D depth sensor manufacturer for object detection and accurate volume measurement processes.

Cube Eye Key Features:

High accuracy: Cube Eye can measure distances with millimeter-level precision, making it ideal for applications that require precise depth information, such as robotics, augmented reality, and industrial automation.

Wide field of view: The camera has a wide field…

3D ToF (Depth) Camera Product | CUBE EYE

The CUBE EYE 3D depth camera is manufactured by meerecompany, a South Korean company that specializes in the development and production of ToF (time-of-flight) cameras.

A time-of-flight 3D depth camera employs time-of-flight techniques to obtain distance and depth data by measuring the round-trip time of light.

The ToF camera emits light through a light source in the camera and receives the light that is reflected by the object. The camera measures the…

High-Quality TOF 3D Depth Camera | CUBE EYE

CUBE EYE is a brand of time-of-flight (ToF) cameras developed by MeereCompany, a South Korean company that specializes in the development and manufacturing of high-tech equipment for the display, semiconductor, solar cell, and medical industries.

ToF (time of flight) cameras use lasers to measure the distance between the camera and the object. Cube Eye is used in a variety of applications, including retail intelligence, surveillance, and 3D scanning.

Cube Eye TOF…