Press release

Digital factory as a start in Industry 4.0

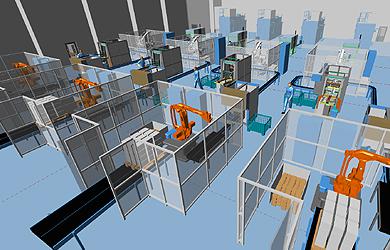

Through Industry 4.0, the entire factory is digitised and automated. The first step for most people is to digitise your own factory.Cambridge, UK and Pittsford, NY – 28 February 2017: Through the digital transformation of society, everything is becoming interfaced, networked and automated. Through Industry 4.0, this trend is also entering the industrial world; the first step should surely be to digitise one’s own factory.

Digital factory is still not standard

Fully digital, or smart, factories have been a growing reality with the big players for many years. Nevertheless, the SME’s seem reluctant to invest, because the added value of a digitised plant or factory has not yet been sufficiently demonstrated to them. This is often due to a lack of awareness in the field of digitisation or Industry 4.0.

The digital factory is expected to generate high growth potential for companies within the next ten years. Nevertheless, this can only be achieved with the necessary know-how and determined will for the changeover. A first step in the right direction is to digitise the company's own buildings and factories. Only then can these be evaluated and optimised accordingly.

The digital factory starts where you are today

It’s very simple to begin your digital factory. Existing building drawings or models can be used to capture the building digitally. Changes and modernisations carried out since the creation of these drawings and models must be made. Then the installation is carried out in the entire plant or factory.

If 3D data is available, this is the optimal starting situation. Should this not be the case, individual plant components must gradually be digitally recorded and captured into the digital model. Laser scanning can be used to quickly help record existing plants.

Ready for Industry 4.0

Industry 4.0 is the new goal for many companies: the potential that digitisation offers can now finally be utilised; a step-by-step approach is required. After the capture of buildings and plants, the digital capture and structuring of the individual processes, structures and data must still take place. This is the only way to find and implement new solutions in the context of Industry 4.0. Without going through the first basic steps, the potential of Industry 4.0 cannot be developed.

Software for the digital imaging of the factory:

http://www.cad-schroer.com/products/mpds4/factory-layout.html?utm_source=PR&utm_campaign=Digifab-Ind4&utm_medium=Portal

The right software to make a start

Successful work primarily involves the right tools. MPDS4 is a very good solution for the digital capture of entire factories or plants. With this, entire production plants can be captured and incorporated in a 3D-layout independent of their size or complexity. The system processes any type of historical data, no matter whether these are provided as raster scans of paper drawings, 2D CAD drawings, 3D models or 3D laser scans. Versatile interfaces ensure high integration into existing system environments. The great flexibility and configurability of the system allows company-specific solutions to be developed.

MPDS4 can be trialled for 30 days free of charge. Video tutorials and documentation are available to provide a simple introduction to the software.

About CAD Schroer

CAD Schroer is a global software development company and engineering solutions provider, helping to raise the productivity and competitiveness of customers working in manufacturing and plant design, including the automotive sector and its supply chain, the energy sector and public utilities. CAD Schroer has offices and subsidiaries throughout Europe and in the United States.

CAD Schroer’s product portfolio includes 2D/3D CAD, plant design, factory layout and data management solutions. Customers in 39 countries rely on MEDUSA4®, MPDS4™ and STHENO/PRO® to provide an efficient, flexible and integrated design environment for all phases of product or plant design – cutting costs while raising quality. CAD Schroer emphasizes close customer partnerships and supports its clients’ objectives through extensive consultancy, training, development, software support and maintenance services.

CAD Schroer UK Ltd

2nd Floor Godwin House

Castle Park

Cambridge UK

CB3 0RA

441223460408

Kate Pottle

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Digital factory as a start in Industry 4.0 here

News-ID: 460307 • Views: …

More Releases from CAD Schroer UK Ltd

Virtual Reality at the PPMA Show 2018

Cambridge, UK and Pittsford, NY – 24 August 2018: Also this year CAD Schroer’s customer Mariani will attend the PPMA show in Birmingham. The PPMA show is the UK's largest processing and packaging machinery exhibition, and is completely free for visitors to attend. CAD Schroer will be supporting Mariani at the show with the latest virtual and augmented reality technologies.

Mariani Presents in Virtual Reality at the show

Mariani is one…

Faster Plant Design & Factory Layout with MPDS4 6.2

MPDS4 version 6.2 offers extensive new functionality and productivity enhancements for plant design and factory layout applications.

Cambridge, UK and Pittsford, NY - 28 June 2017: MPDS4 version 6.2 includes new functionality for improved reporting and a simpler user experience. The optimisation of interfaces simplifies data exchange with customers and suppliers.

Simpler and faster design

The main focus of version 6.2 is to achieve a simpler user experience through improved functionality, and faster…

Plan systems and factories even better with MPDS4 6.2

Version 6.2 offers lots of new productivity improvements and functions to the plant construction and factory planning software MPDS4.

Cambridge, UK and Pittsford, NY - 21 June 2017: MPDS4 version 6.2 includes a large amount of new functions for improved reporting and simpler handling. The expansion and optimisation of interfaces simplifies the exchange of data with customers and suppliers.

Simpler and better planning

The main focus of version 6.2 was to achieve easier…

Free 3D factory layout software for the designers of tomorrow

The MPDS4 3D Factory Layout Software is available free of charge for students, as well as for educational and research facilities.

Cambridge, UK and Pittsford, NY - 17 May 2017:

Lecturers and students benefit from a multi-user 3D factory engineering suite that is easy to administer and provides integrated 2D drafting software, as well as extensible catalogues of 3D components for all major design disciplines.

Factory Layout Engineering Software – Free Educational…

More Releases for Industry

Hydro Lubricants Market Size, Analysis, and Forecast Report 2018 to 2026(By Indu …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Hydro Lubricants Market Insights, Trends & Future Development Status Recorded du …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Global Pyrite Market 2019 | Applications: Jewelry Industry, Sulfur Compounds Ind …

The major factor driving the pyrite market is the rising demand of jewelry and sulfur compounds market. This report researches the worldwide Pyrite market size (value, capacity, production, and consumption) in key regions like North America, Europe, Asia Pacific (China, Japan) and other regions. This study categorizes the global Pyrite breakdown data by manufacturers, region, type, and application, also analyzes the market status, market share, growth rate, future trends, market…

Lipase Enzymes Market Future Forecast Indicates Impressive Growth Rate (Segmenta …

Market Outlook

Increased consumption of processed food and dairy products among consumers has fuelled the demand and supply of lipase enzymes over the years. Lipase is an enzyme that catalyzes the hydrolytic reaction of fats, and reduces the formation of glycerol and fatty acids in all living organisms. It plays a vital role in the process of digestion by transporting and processing the ester bonds in triglycerides. Due to the varied…

Big Bag Connection System Market Segmented By technology Automatic, Semi-Automat …

Global Big Bag Connection System Market: An Overview

The key advancement in automation encourages manufacturers to adopt smart systems to increase productivity and to facilitate timely production. Owing to the perception of consumers as well as manufacturers regarding health and hygiene of product, the big bag connection system market is anticipated to propel during the forecast period. Big bag connection system ensure dust -free docking of big bags and provide flexibility…

Europe Plastic Pallet Market Size, Shares, Forecast Report 2016 : Food Industry, …

This report studies sales (consumption) of Plastic Pallet in Europe market, especially in Germany, UK, France, Russia, Italy, Benelux and Spain, focuses on top players in these countries, with sales, price, revenue and market share for each player in these Countries, covering

ShangHai Pallet Plastic Industry Co., Ltd.

Shanghai Lika Plastic Manufacturing Co., Ltd.

Guangzhou Plastic Industrial Corporation Ltd

Shandong Liyang Plastic Molding Co.,Ltd

Xinding Plastic

ZheJiang Primacy Plastic Industry Co., Ltd

Shanghai Qinghao Plastic Pallet Manufacture…