Press release

Solving the productivity puzzle with technology and training from Intertronics

With manufacturing productivity in Q4 2016 growing by 1.7% on the previous quarter* – but overall growth still lagging behind the curve – the UK economy continues to be haunted by the “productivity puzzle”. Engineering adhesives specialist Intertronics works with its customers to enhance their productivity in order to compete in both home and export markets.The latest Executive Survey from manufacturers’ organisation EEF clearly confirms a broad recognition of this need. Findings indicate that in order to achieve their business goals in 2017, UK manufacturers will achieve greater productivity in three ways: 1) process innovation 2) investment in technology and innovation, and 3) continued work to ensure flexible supply chains. Often the approach is quite holistic, tackling more than one of these considerations at a time.

56% of survey respondents reported that they will be undertaking process innovations to increase productivity. Medium sized firms (those with 101-250 employees and quite possibly the unsung heroes of our manufacturing economy) are the most likely to do this, with seven in ten citing it as an action they will undertake. Half of companies surveyed said they expect to increase investment in technology and innovation in the next 12 months.

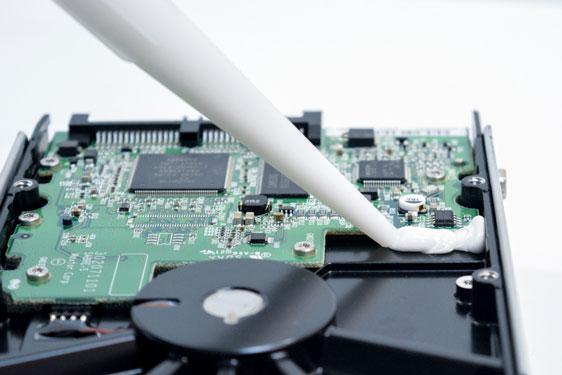

Intertronics says that it is successfully helping both existing and new customers with process innovation in areas such as very fast light curing of adhesives and coatings using UV and/or visible light, and sophisticated mixing and degassing. They are investing in technology and innovation in the form of material application automation and precision, and surface treatment. Customers also enjoy reliable, fast delivery and, where required, flexible shipments, consistent with supply chain efficiency.

Intertronics Managing Director Peter Swanson explains: “Our focus is on the use of advanced engineering adhesives as an efficient and reliable fastening method suited to automated assembly, in the form of our latest materials dispensing and curing technologies. For example, UV/visible light cure adhesives that cure in seconds, THINKY mixing and degassing equipment, alternative dispensing technologies, our range of dispensing robots and advanced surface treatment techniques are all helping manufacturing companies at all levels of automation maturity to enhance their processes and productivity.”

Intertronics organises regular seminars to demonstrate how the latest technologies and products can play a major role in this. In addition, the company’s Oxford-based Technology Centre is in constant use, enabling both design and production engineers to evaluate and compare adhesives, coatings, sealants and equipment in the context of their assemblies and processes – enhancing competitiveness, product quality and reputation.

For further information please see www.intertronics.co.uk/productivitypuzzle or visit the Intertronics blog at www.adhere.uk.com – also see www.youtube.com/intertronicsadhere.

*Source: Office for National Statistics

"adhere” from Intertronics provides quality adhesive solutions to high technology, high performance assembly industries, incorporating outstanding levels of technical support and customer service.

The adhere concept covers their range of adhesives, encapsulants, coatings, sealants and tapes as well as the associated dispensing, curing and surface preparation equipment and materials used in the manufacturing and assembly processes. Also their Opti-tec brand of adhesives.

Intertronics have been certified to ISO 9001:2008 standard demonstrating their commitment to customer service and quality in delivery. Certification proves that the Intertronics quality management system ensures consistency and a continuous improvement ethic, leading to high levels of performance and customer satisfaction.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

blog: www.adhere.uk.com

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Solving the productivity puzzle with technology and training from Intertronics here

News-ID: 540660 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for Solving

RupeeDot : Disrupting Auto Finance & Solving Dealer Challenges

RupeeDot: A Fintech Disruptor in Auto Finance RupeeDot is not only another fintech company; it's a disruptor in India's auto finance space. It's a Pune-based company operating under Indicorn Financial Services Private Ltd and works as a facilitator between lenders and borrowers. Imagine it as a dating website for car loans. By tying up with banks, NBFCs and alternative lenders, RupeeDot collects numerous loan options so customers don't need to apply separately to each…

Problem solving method of conveyor chain

The conveying chain is the same as the transmission chain. The precision conveying chain is also composed of a series of bearings, which are fixed by the chain plate with restraint, and the positional relationship between each other is very accurate.

Each bearing consists of a pin and a sleeve on which the rollers of the chain rotate. Both the pin and the sleeve undergo surface hardening treatment, which allows hinged…

Chinese Pipe Expansion Joints: Solving Thermal Expansion Issue

Image: https://ecdn6.globalso.com/upload/p/527/image_product/2024-09/img_20230904_132436_resize-7.png

1. Impact of thermal expansion and contraction on pipeline systems

When the temperature of the pipeline system changes, its length will slightly extend or shorten. Although this change seems insignificant, when multiple pipelines are affected at the same time, the cumulative expansion and contraction will become considerable. If not controlled, the pipeline may be damaged due to excessive expansion and contraction, and even cause pipeline rupture or leakage at the…

Cheap CAPTCHA Recognition and Solving Service

CAPTCHA = Completely Automated Public Turing Test To Tell Computers and Humans Apart

A CAPTCHA is a type of challenge-response test used in computing to determine whether the user is human. The term was coined in 2003 by Luis von Ahn, Manuel Blum, Nicholas J. Hopper, and John Langford. The most common type of CAPTCHA was first invented in 1997 by two groups working in parallel.

They could be easily solved by…

Solving pharma dosing challenges through smart automation

Peptides play a critical role in the modern physician's toolkit. But peptides and related substances present unique manufacturing challenges. Small quantities of expensive materials are typically hand-measured: Product is moved from a single-source container to a fixed target-weight batch in a time-consuming and error-prone method that often results in costly overfills. Is there a better way?

Manually, sale weights ranging from 1 mg to several-100 mg often require 2 to 3…

Solving Your Term Paper Problems 101

Few of the most dreadful rites of passage that every student must overcome a few times in his academic life are the staggering term papers and dissertation writing. These are major requirements before graduating or passing a certain subject. Unfortunately, not everyone find these tasks easy. Very limited time for preparation, insufficient knowledge of topic and sources, and inadequate writing skills are only some of the factors that make thesis…