Press release

Free UV Curing Guide Offers Top Tips from Intertronics

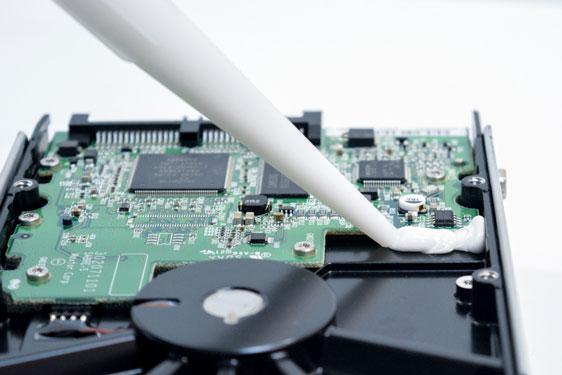

The curing of materials like adhesives, coating, encapsulants, potting compounds, temporary masking materials or gaskets with UV light offers many process advantages, and can deliver productivity enhancements to manufacturers. The ability of the technology to deliver full cure in seconds (rather than minutes or hours) is a prime example.The materials are predominantly single part (no mixing) and only cure on demand, so application or dispensing is straightforward and readily automatable. The light curing process looks quite simple, and indeed it is. But like most things, there is a learning curve.

The latest publication from Intertronics, Top Tips for Getting the Best from your UV Curing Process, breaks down the elements of this technology. The aim is to give a better understanding of the way that UV curing works and to discuss the process variables. A good grasp of the fundamentals will help engineers, technicians and operators to set up an established process which is effective, robust and repeatable. Along the way, there are some rules of thumb and tricks of the trade to make things easier and to ensure success.

The free guide discusses some of the differences between conventional UV curing lamps and the latest lamps based on LED technology.

It is available from www.intertronics.co.uk/technical-resources.

Intertronics supplies adhesives, coatings, sealants and equipment to customers with high technology, high performance assembly applications. Their customers are manufacturers in industries such as electronics, medical devices, plastics, optical, automotive, energy, defence and aerospace.

Intertronics specialise in adhesives and adhesive systems, namely bonding, coating, sealing, encapsulating, potting, masking and gasketing products, together with the most appropriate equipment and accessories for surface preparation, mixing, application, dispensing, and curing them. The provision of insightful technical and applications guidance is a cornerstone of their business. Intertronics can help you find the optimal materials and processes for the manufacture, assembly or repair of your products, safeguarding and enhancing performance and integrity and, in turn, your profitability and reputation.

Ever since being established in1979, when their main market was the printed circuit board assembly industry, Intertronics has enjoyed a reputation for customer focus, excellent service and post-sales support. They now supply over 3,000 regular customers, including multinational manufacturers, production facilities, specialist design and development businesses, universities, training organisations and government establishments.

The Intertronics Technology Centre, located in Oxfordshire with excellent road and rail links, is custom-designed for hands-on demonstrations and trials, hosted by their product specialists.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Free UV Curing Guide Offers Top Tips from Intertronics here

News-ID: 891972 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for Curing

Epoxy Curing Agent Market 2021 Analysis and Research on Chemical Segment- Atul L …

Global Epoxy Curing Agent Market 2021-2025 is a comprehensive report which provides a detailed overview of the major driver, opportunities, challenges, current market trends and strategies impacting the Global Epoxy Curing Agent market in conjunction with calculation and forecast of size, share, and growth rate analysis. Combining the analysis capabilities and knowledge integration with the relevant findings, the report has foretold the robust future growth of the Epoxy Curing Agent…

Global Concrete Curing Compounds Market, By Type (Synthetic Resin Curing Compoun …

Global “Concrete Curing Compounds Market” research report covers an introduction of Concrete Curing Compounds Industry which will guide the companies role-play within the Concrete Curing Compounds Industry to know the market and create the strategies for their business growth accordingly. The report also enfolds insightful analysis of competition intensity, segments, environment, trade regulations, and product innovations to render deep comprehension of the complete Concrete Curing Compounds market structure.

Get Sample Copy…

UV Curing Systems Market: Increasing demand of UV LED based curing over conventi …

The global UV curing system market accounted for US$ 1,163.4 Mn in 2017 and is expected to grow at a CAGR of 9.6% during the forecast period 2018 – 2025, to account for US$ 2,409.8 Mn by 2025.

The UV curing system market has experienced significant growth and adoption rate in the past few years and is expected to experience notable growth and adoption in years to come. UV Curing systems…

Epoxy Curing Agents Market Report 2018: Segmentation by Type (Amine-Based Curing …

Global Epoxy Curing Agents market research report provides company profile for Evonik Industries (Germany), Hexion Inc. (US), Huntsman Corporation (US), Cardolite Corporation (US), BASF S.E. (Germany), Cardolite Corporation (US) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year…

Drying Curing Equipment Market Report 2018: Segmentation by Product (UV Drying C …

Global Drying Curing Equipment market research report provides company profile for Lumen Dynamics, Miltec, Nordson, AMS, Kyocera, Panasonic, IST METZ, Heraeus, GEW, Phoseon and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report…

Folex endorse GEW UV curing technology

Folex Coating GmbH in Cologne, Germany have added UV curing capability to their principal coating line.

Folex is a coating and finishing specialist converting a wide variety of films and foils for offset, gravure and inkjet printing applications and the electronics industry.

In 2016 Folex installed a UV curing station on their principal coating line and integrated a GEW-made 170cm-wide NUVA2 UV system with an 18kW RHINO electronic power supply. The UV…