Press release

From Challenges to Solutions: Enhance The PE-RT Pipes with Silicone Masterbatch and PFAS-Free Additives

PE-RT (Polyethylene of Raised Temperature Resistance) heating pipes are made from PE-RT, a high-temperature resistant polyethylene material specifically developed for use in heating systems. These pipes are non-crosslinked polyethylene pipes suitable for hot water applications. Some emphasize their non-crosslinked nature, referring to them as "non-crosslinked high-temperature resistant polyethylene pipes."With the advancement of plastic technology, various plastic pipes have become available for indoor heating systems. Plastic pipes offer numerous advantages, including smooth inner surfaces, low resistance to heat transfer, resistance to acids and alkalis, long service life, and easy installation. In recent years, PE-RT has gained widespread use in underfloor heating systems, and as a new generation of heating-specific piping material, it is gradually becoming the mainstream choice in the underfloor heating market.

However, PE-RT pipes still face production and performance challenges in heating applications:

1. In heating systems, oxygen in the water can enter the pipes and promote bacterial growth, leading to the formation of microbial slime on the pipe walls. This buildup significantly reduces the heat conduction efficiency of the pipes, negatively impacting the performance of the heating system.

2. During the production of PE-RT pipes, the inner wall can develop wrinkles, which can reduce the flow rate of hot water inside the pipe. These wrinkles can also provide a surface for microorganisms to attach and multiply, further contributing to biofilm formation and reducing heating efficiency.

Traditional Solutions and Their Limitations

Fluoropolymer-based processing performance additives (PPAs) have been used to address these issues by smoothing the pipe's inner surface, reducing friction, and enhancing water flow. However, these additives often contain PFAS (Per- and Polyfluoroalkyl Substances), which pose serious environmental and health risks. As regulations tighten and consumer demand for sustainable solutions grows, the industry is seeking safer, eco-friendly Alternatives to PFAS.

Introducing a sustainable multi-functional masterbatches: SILIKE's Silicone Masterbatch and PFAS and fluorine-free alternatives solutions

These PFAS-Free PPA for Functional Compounds Solutions offer several key benefits that address both the challenges in PE-RT pipe production and the environmental concerns associated with fluoropolymers. Here's how our solutions can transform your underfloor heating systems made of PE-RT (Polyethylene of Raised Temperature Resistance) material:

1. Silicone masterbatch and SILIMER series PFAS Free PPA enhance the durability of PE-RT pipes by improving resistance to wear and scratches. This ensures that the pipes maintain their performance over a longer period, even under challenging conditions.

2. One of the most significant advantages of silicone masterbatch and SILIMER series PFAS Free PPA is its ability to reduce sliding friction within the pipes. This promotes better water flow and helps prevent the formation of microbial slime, resulting in a self-cleaning effect that improves overall heating efficiency.

3. By combining heat-resistant polyethylene with silicone masterbatch and SILIMER series PFAS Free PPA, the new generation of PE-RT pipes offers a longer service life. This not only enhances the reliability of heating systems but also reduces the need for frequent replacements, leading to cost savings and environmental benefits.

4. Safer and Greener polymer processing aids Alternatives: The use of PFAS-free PPAs eliminates the environmental and health risks associated with fluoropolymers. These Plastic Additive Functional Masterbatch PPA [https://www.siliketech.com/fluorine-free-ppa/] Masterbatch provide a safer and more sustainable solution without compromising the performance of the pipes.

For manufacturers dedicated to leading the way in the PFAS-Free Additives For Pipe Extrusion [https://www.siliketech.com/fluorine-free-ppa/] Materials industry, embracing sustainable additives in PE-RT pipe [https://www.siliketech.com/fluorine-free-ppa/]production is a strategic and forward-thinking decision. These innovations not only improve the long-term performance of heating systems but also contribute to the overall sustainability of the industry, making them essential for future-ready building solutions for underfloor heating systems.

Act now to elevate your PE-RT heating pipe production by incorporating SILIKE's Silicone Masterbatch and PFAS-free PPAs into your processes. Create self-cleaning, wear-resistant pipes that withstand the test of time while fostering a healthier and more sustainable environment.

To learn more, please visit the websites of manufacturers offering silicone masterbatches or PFAS-free polymer processing aids (PPAs) at www.siliketech.com, or feel free to contact Amy Wang at amy.wang@silike.cn.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=from-challenges-to-solutions-enhance-your-pert-pipes-with-silicone-masterbatch-and-pfasfree-additives]

Country: China

Website: https://www.siliketech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release From Challenges to Solutions: Enhance The PE-RT Pipes with Silicone Masterbatch and PFAS-Free Additives here

News-ID: 3871968 • Views: …

More Releases from ABNewswire

Exploring the Impact of U.S. Government Shutdown on the Global Markets - An Excl …

Image: https://www.abnewswire.com/upload/2025/11/6ab92174e3dc0ee6c1bfafc8e655cfb4.jpg

A shutdown of the U.S. federal government, when Congress fails to pass spending legislation and many agencies cease non-essential operations, poses a material risk to the economy. But when viewed through the lens of market history and global asset flows, the evidence suggests that such shutdowns are often absorbed by the markets and, in several ways, may present tactical opportunities for globally diversified investors.

1. What a U.S. Government Shutdown…

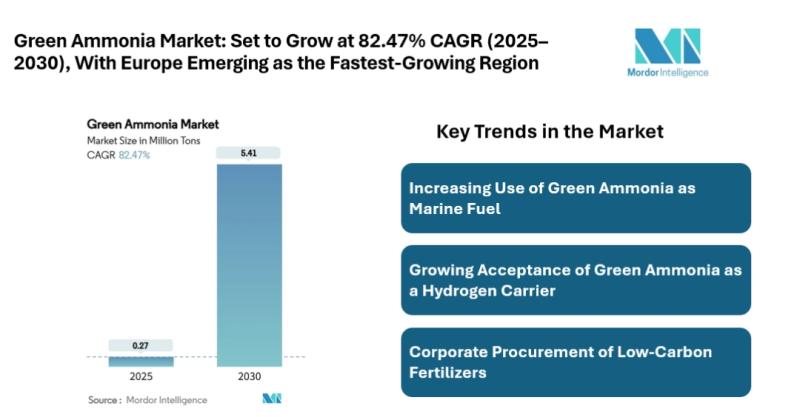

Green Ammonia Market size growing at CAGR of 82.47% by 2030 | Rising Fertilizer …

The latest research by Mordor Intelligence covers the "Green Ammonia Market," delivering insights into market dynamics, drivers of growth, and long-term forecasts.

Green Ammonia Market Overview:

The global green ammonia market is expanding steadily as countries accelerate the shift toward low-carbon fertilizer, marine fuel, power generation, and hydrogen transport solutions. The green ammonia market [https://www.mordorintelligence.com/industry-reports/green-ammonia-market?utm_source=abnewswire] size is expected to grow from 0.27 million tons in 2025 to 5.41 million tons by 2030,…

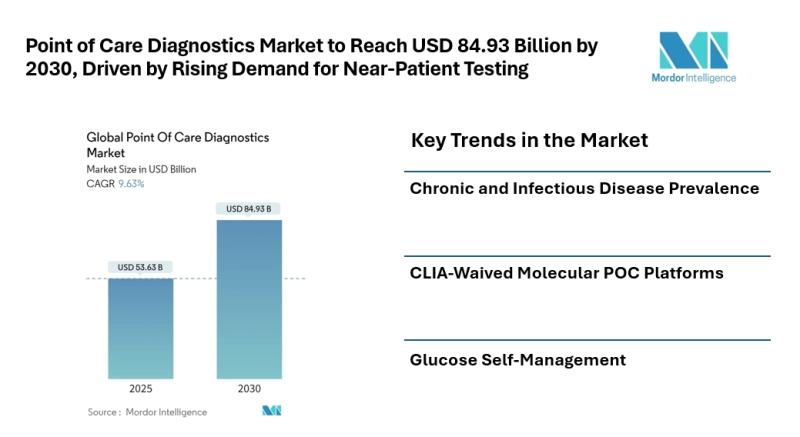

Point of Care Diagnostics Market to Reach USD 84.93 Billion by 2030, Driven by R …

Mordor Intelligence has published a new report on Point Of Care Diagnostics Market offering a comprehensive analysis of trends, growth drivers, and future projections.

Introduction

The Point Of Care Diagnostics Market [https://www.mordorintelligence.com/industry-reports/point-of-care-diagnostics?utm_source=abnewswire] size is estimated at USD 53.63 billion in 2025, and is expected to reach USD 84.93 billion by 2030, at a CAGR of 9.63% during the forecast period (2025-2030). The market's growth is fueled by the increasing need for rapid,…

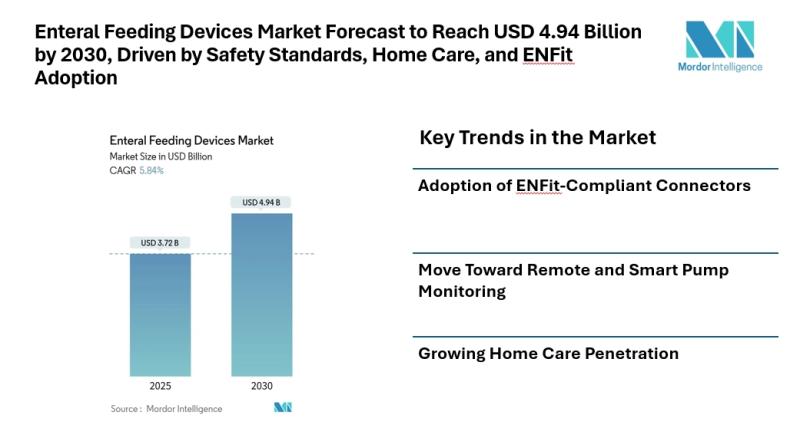

Enteral Feeding Devices Market Forecast to Reach USD 4.94 Billion by 2030, Drive …

Mordor Intelligence has published a new report on enteral feeding devices market offering a comprehensive analysis of trends, growth drivers, and future projections.

Introduction

The enteral feeding devices market [https://www.mordorintelligence.com/industry-reports/enteral-feeding-devices-market?utm_source=abnewswire] is projected to grow from approximately USD 3.72 billion in 2025 to USD 4.94 billion by 2030, according to a recent report by Mordor Intelligence. The growth reflects a compound annual growth rate (CAGR) of around 5.84 percent, driven primarily by technological…

More Releases for PFAS

PFAS-Free Synthetic Turf Solutions | Eco-Friendly Artificial Grass and Non-PFAS …

This article delves into the key challenges and difficulties faced by the synthetic turf industry in achieving a "PFAS-free" transition, with a focus on innovative non-PFAS additive solutions designed to offer a sustainable path that balances high performance, safety, and environmental responsibility.

Challenges in Traditional Synthetic Turf Manufacturing | PFAS Risks Performance vs. Safety Dilemma

Traditional synthetic turf often relies on fluorinated polymers to achieve:

- Exceptional UV and weather durability

- Stain and…

Global PFAS-free Membranes Market Outlook Report 2025

Global Info Research's report is a detailed and comprehensive analysis for global PFAS-free Membranes market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the PFAS-free Membranes market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of…

PFAS-free Polymer Membranes Market Demand Analysis Report 2025

Global Info Research announces the release of the report "Global PFAS-free Polymer Membranes Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides a detailed overview of the PFAS-free Polymer Membranes market scenario, including a thorough analysis of the PFAS-free Polymer Membranes market size, sales quantity, average price, revenue, gross margin and market share.The PFAS-free Polymer Membranes report provides an in-depth analysis of the competitive landscape,…

PFAS Filtration Market: Advanced Solutions for Persistent Contaminants

𝐆𝐥𝐨𝐛𝐚𝐥 𝐌𝐚𝐫𝐤𝐞𝐭 𝐭𝐨 𝐑𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑.𝟖𝟓 𝐁𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟑 𝐀𝐦𝐢𝐝𝐬𝐭 𝐑𝐢𝐬𝐢𝐧𝐠 𝐏𝐅𝐀𝐒 𝐂𝐨𝐧𝐜𝐞𝐫𝐧𝐬 𝐚𝐧𝐝 𝐑𝐞𝐠𝐮𝐥𝐚𝐭𝐨𝐫𝐲 𝐏𝐫𝐞𝐬𝐬𝐮𝐫𝐞𝐬

The PFAS filtration market is experiencing substantial expansion, driven by escalating concerns over per- and polyfluoroalkyl substances (PFAS) contamination in drinking water, industrial effluents, and consumer goods. Valued at USD 2,089.50 million in 2024, the market is projected to grow at a CAGR of 7.20%, reaching USD 3,855.56 million by 2033. This growth is fueled…

PFAS-free Polymer Processing Aids (PFAS-Free PPA Additives), a solution to the p …

In the plastic processing industry, die build-up is a common problem that can lead to surface defects in products, affecting product quality and production efficiency.

Die build-up refers to the accumulation of material at the outlet of the mold during plastic processing, forming deposits that are difficult to remove. This phenomenon usually occurs in injection molding, extrusion and other processes, especially in the processing of high viscosity and high melting point…

PFAS: What they are & how to avoid them

These "Forever Chemicals" have existed for what seems like forever, but they've just recently begun making headlines. Here's what you need to know about these troubling compounds.

In the world we live in today, the alphabet soup of acronyms for both good and bad substances can make your brain feel like mush. But there's one that you've probably seen popping up more and more. And it's one worth remembering.

PFAS, or "Forever…